Audis

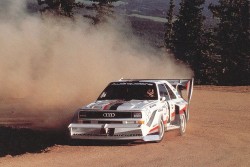

The Audi quattro

Pikes Peak Paralogism

Ur-quattro Beginnings

The More Things Change

My Next-door Neighbour’s Audi (and Mine)

Audi Wins its First Australian Motorsport Title

NSU Ro80

A Fast Lap Around Bathurst

Audi Historical Highlights

Jones Makes History for Audi

Peugeots are better than Audis

Audi wins Le Mans 2000

Audi repeats Le Mans win 2001

Audi achieves Le Mans hat trick

Audi TT 3.2

The August Horch Museum

Audi RS4 supercar

Audi Diesel wins Le Mans

The Audi quattro

By Jeff Whitten

June 1992

The original or ‘Ur’ Audi quattro (note the lower case ‘q’) has been withdrawn from sale after a decade of production and more than 11,000 units. Make no mistake, the quattro will be sadly missed. Every rally fan will have memories of the quattro whether it be photos in a magazine, the glorious sight and sound on a Club video or even a rare memory of the car itself, its 5 cylinder engine belting out its familiar spine-tingling howl. However, thanks to LNC Industries not importing it, the quattro was an unknown vehicle in Australia and its history may be somewhat of a mystery.

Germany’s finest-ever rally car was introduced to the world when a number of other manufacturers were about to release new 2-wheel-drive rally cars onto the international scene. The quattro's arrival set these manufacturers back on their heels, and to pen a cliche, quickly sent them back to their drawing boards.

Revealed to the world at the Geneva Motor Show in March 1980 and campaigned in world rally events from 1981, Audi’s 4-wheel-drive, 5-cylinder turbocharged wonder wasn't the first production vehicle in the world to employ 4WD for its passenger vehicles, but it immediately became the most successful. Few of the opposition could match its awesome traction advantage from its new fangled transmission system, especially on gravel.

So successful was the quattro’s early career that it won the second world championship event that it entered. By the end of the first season Hannu Mikkola, the new Audi Team driver, had won the most demanding event in Europe, the Lombard RAC Rally, and from that moment on the quattro was on a roll.

The combination of new technology, 4WD, an enormously powerful 5-cylinder turbocharged engine, and the driving skill of Hannu Mikkola, took the inexperienced Audi team to the top of the ladder in an indecently short time.

For a while, most observers thought that the quattro’s supremacy was partly due to its superior straight-line performance. However, road tests of the day showed that the big, heavy Audi was no faster than the current Opel and Ford rally cars. Its winning ability was simply due to the uncanny knack of putting power to the ground with minimal wheel spin. Its superiority was all about traction and roadholding. True, it was not unbeatable on tarmac, where a well-driven Ford Escort or an Opel Mantra could see it off on most occasions. But on events like the Swedish, 1000 Lakes, the Monte Carlo and so many other loose surface rallies, the quattro was the yardstick by which the others had to measure themselves.

Suddenly rear-drive was no longer good enough. ‘4WD’ and ‘turbocharging’ were the in-words of the 1980s. But as well as changing the face of rallying, many of today's top drivers cut their teeth in a quattro. Drivers like Hannu Mikkola, Stiq Blomqvist, Walter Röhrl, Michelle Mouton, Malcolm Wilson and numerous others all piloted the quattro. While Franz Wittman was the first driver to win an event in the quattro, Mikkola was the one to put the Audi name well and truly on the map.

Mikkola was brought to Audi in 1980 as the road car was nearing its pre-release development phase. The Finn was suitably impressed with the car, and agreed to drive it the following season.

To say he set the rallying world on its ear by taking an 11-minute win on the 1981 RAC Rally would be an understatement. Such a large winning margin was unheard of, but became more astonishing considering a mid-event roll that cost him valuable time. Yet he still led home drivers like Ari Vatanen, Stiq Blomqvist and Pentti Airikkala.

The Audi was making a habit of establishing ‘firsts’ in rallying, for it was in that first season that the delightful and very talented Michele Mouton made history by taking the car to victory in a round of the Manufacturers Championship, the first lady ever to win a round of the World series.

It didn't all go Audi's way in that first year of competition. While wins in the Swedish, RAC and San Remo rallies were highlights; the rest of the season was fairly unremarkable. The quattros were disqualified in Greece for fitting a supplementary battery in the cockpits, and Mikkola, Mouton and Wittman were thrown out of the event.

But better was still to come, and 1982 brought more dramatic achievements. The high-tech German car had shown it could outgun anything the opposition could throw at it, so they began frantically redesigning 4WD machinery under the new Group B rules, which had just come into effect.

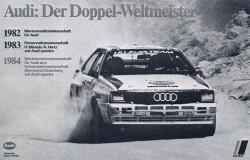

Stiq Blomqvist had secured a works drive with Audi, and celebrated this with wins on the 1982 Swedish and San Remo. Michele Mouton won the Portugese, Acropolis and Rally of Brazil, and Mikkola dominated the 1000 Lakes and the RAC. For good measure, quattros were also second on the 1000 Lakes, the RAC and San Remo as well. Hannu Mikkola became the most successful rally driver of all time, while Audi won the Manufacturers World Rally Championship, the first German company ever to do so.

Hannu Mikkola and Arne Hertz won the Drivers World Rally Championship in 1983, along with second place for Audi, behind Lancia, in the Manufacturers Championship. Audi won thirteen national championships with the quattro that year. The new Audi Sport quattro was glimpsed for the first time at the 1983 Frankfurt Show in September.

Winning both the Manufacturers and Drivers World Championships had always been Audi's goal, and they had won the first in 82 and the latter in 83. In 1984 they would win both! This was due to two factors; one being that Walter Röhrl had joined the team as a driver, and the other was the debut of the Group B Audi Sport quattro.

Walter Röhrl was a sensation in the Sport quattro, and the German team swept all before them that year. While the older long A2 quattro was good, the Sport quattro was unbelievable. Its wheelbase was 320 mm shorter than the earlier model, and the 5-cylinder, twenty-valve turbo engine produced 450 bhp, compared to 360 bhp in the A2 model.

For a while in 1984 the Audis steamrollered on - until Peugeot unveiled their 205 T16; the era of the Group B supercars had begun. When Ari Vatanen brought his 205 home well clear of 4th placed Blomqvist in the 1000 Lakes, it seemed the quattro’s dream run might well have ended. With an equally powerful engine and 4WD to match, the Peugeot showed a clean pair of heals to the Audi. While the 205 had a mid mounted engine and near perfect balance, the quattro suffered from a big, heavy engine sitting forward of the front axle, causing excessive understeer.

But despite its faults, the development that had gone into the Sport quattro still rendered it more than a match for the new Peugeots. The Sport quattro made its debut on that year's Ivory Coast rally, and in the hands of Blomqvist won with relative ease. Mikkola was placed second, and the results achieved were sufficient to net Stiq and his navigator Bjorn Cederberg the Drivers Championship and the Makes title for Audi. But that was the last tune the quattros had it all their own way.

1985 saw even more Group B madness unfold. Peugeot had the 205 T16, Lancia the powerful Delta S4 (often even faster than the Peugeot), Austin Rover had the Metro 6R4 and Ford showed their RS200. Audi retained their Sport quattros, this time in evolution S1 form with just over 500 bhp. Yet Audi had been surpassed by other makers, who went one better. For the S1 Sport quattro was still based on a road car, while the Peugeot, Lancia and Metro were far removed from production vehicles. Both the Makers and Drivers titles were won by Peugeot and Timo Salonen, but Walter Röhrl took the San Remo in the S1, his first and only win that year.

1986 saw the final, most powerful version of the quattro arrive. With the updated S1 Sport, there was no mistaking that it was a purpose-built rally car. Bedecked with huge wings, spoilers and other aerodynamic aids, the updated S1 was an enormously powerful beast. Horsepower jumped to over 600 bhp, coupled to a 6-speed semi-auto gearbox. However, the power outputs of the Peugeots and Lancias were about the same, and it took super drivers to handle these twitchy, brutish cars.

The writing was on the wall for Group B when fatal accidents started occurring at some events. When an RS200 Ford ploughed into a crowd of spectators in Portugal, killing three of them, the event was abruptly terminated when the leading manufacturers withdrew their cars on the spot. Audi withdrew its teams from the World Rally Championship, and ended their Group B participation for good.

The end of Group B racing itself came shortly afterwards, when the brilliant Henri Toivonen and his co driver Sergio Cresto were killed when their car speared off the road during the Tour de Corse.

And so the quattro era drew to a close, and with it one of the most exciting periods in rallying history. Anyone who has had the privilege of standing by the side of a special stage to watch a works quattro thunder by knows only too well the awesome sight they presented.

Australia was only fortunate enough to have one original quattro compete in this country. Queenslander Geoff Key's example was a familiar sight in a number of events around the country until its untimely end in a fire last year.

Now all reminders of the quattro era have gone, with production ending last year in Germany.

Except for one thing. Any rally car worth its salt today has least two by-products of the Audi quattro era – four-wheel drive and turbocharging. And for that reason alone we can mourn the passing of the world's original and most spectacular supercar.

Pikes Peak Paralogism

By Phil Matthews

June 1992

One of the current TV ads for Peugeot shows off its sporting prestige by mentioning the result of the Pikes Peak hillclimb in 1988, when 405 16T driver Ari Vatanen won the event and set a record which still stands today. Quite true, but it doesn’t tell the story with anything like the correct balance.

Pikes Peak is a 4,301 m mountain in the Colorado Rocky Mountains, and is the scene for the most famous hillclimb event in the world. For teams and drivers alike, it demands endurance and speed over the 19.96 km gravel road, which includes 157 unguard-railed corners in the climb from 2,866 m up to the 4,301 m summit (Mt Kosciusko is only 2,230 m high.)

Hillclimbs have been held there since 1916, when Rea Lentz in a Romano Special won in a time of 20 minutes 55.6 seconds. VWs and their derivatives have competed since the 1960s, when classes were arranged for open wheelers, stock cars, and open and production rally cars. VW and Porsche-engined buggies, rails and Bajas have proved successful, particularly when turbocharged.

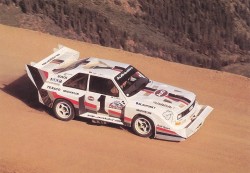

VW themselves attacked Pikes Peak from 1985 to 1987 with different twin-engined Golfs, the most extreme example having two 16V 1800cc turbo engines mounted longitudinally! Audi’s first attempt was also in 1985, when Michele Mouton blasted a Sport quattro to the top in a winning 11 minutes 25.39 seconds, a record then. How humiliating for the good ol’ boys in their big super stock Chevys and Dodges, to be beaten by an attractive woman with painted fingernails!

In 1986 Audi was back again, this time with Bobby Unser Sr. driving an improved Sport quattro. It’s hardly surprising that he won the event, but what is amazing was his time; 16 seconds quicker than Michele Mouton’s effort the previous year, with 11 minutes 9.22 seconds.

In 1987 things got serious. Peugeot appeared for the first time with specially-prepared rear-engined 205 turbo 16s, driven by ‘87 Paris-Dakar winner Ari Vatanen, five-time Safari rally winner Shekhar Mehta and Italian rallyist Andrea Zanussi. This was a souped-up version of the awesome Group B rally cars that had been outlawed the previous year. Other ex-Group B cars included an Austin-Rover M1 Metro 6R4, Ford RS 200s, 4WD Mazda RX7s as well as the usual open wheelers and super stock cars. Audi’s only entrant was a ‘batmobile’ S1 Sport quattro driven by world champion Audi works rally driver Walter Röhrl.

The winner? Although the Peugeot was fastest in practice, the event went to the amazing Walter Röhrl, who blasted the Audi to the top in an amazing 10:47.85, shattering Bobby Unser's record by 21.4 seconds! This was Walter Röhrl’s first ever attempt at Pikes Peak, and he beat Ari Vatanen’s Peugeot by more than 15 seconds. The best V8 open wheeler buggies were a further 20 seconds behind, with the ungainly super stockcars more than one and a half minutes off the pace.

Audi did not return to Pikes Peak in 1988, concentrating instead on the USA TransAm circuit-racing series (which they went on to win!) with the Audi 200 quattro. They had proved their point.

In Audis absence, Ari Vatanen did go on to win the 1988 Pikes Peak, the last time the event saw the awesome Group B rally cars, with a record time of 10:47.22 This is the basis of the Peugeot TV ad, and was also the basis of a spectacular short film called ‘Climb Dance'.

But on his second attempt, and with twelve months extra development under their belt, Ari Vatanen and Peugeot could only beat Walter Röhrl’s time by 0.63 seconds, over a distance of nearly 20 km! That’s only a 0.097% improvement. Compare that with the huge leaps by which Audi would improve each year.

And here’s some food for thought: After his 1987 record, Walter Röhrl admitted that he had made many mistakes (being his first attempt), and that should he try again he could shave a further 25 seconds off his time! What a shame that never came about.

Why is it that Audi, with a better rally competition history than Peugeot, are not promoted as such by the Australian importers TKM, who share both marques?

PS. The printed version of the Peugeot ad also states that should the car go over the edge, it will accelerate downwards at “32 feet / sec / sec.” This is beneath contempt. The acceleration of free fall (g) is scientifically recognised as 9.807 ms-2 (although it varies slightly with locale). The French, in particular, would be insulted at the use of medieval units to sell their cars!

Ur-quattro Beginnings

By Graham Robson

March 1993

In the mid-‘seventies, the West German military provoked the development of the precursor to the Audi Ur-quattro. Their requirements dictated a replacement for their ageing cross-country vehicle, the DKW Munga. The VW/Audi group successfully tendered to design and build such a vehicle, whose underpinnings became the basis of the Ur-quattro's success.

Ferdinand Piech (then Audi R&D Director) oversaw the project, which was to develop a vehicle called the Iltis. It received large orders from the West German and Dutch army. The Iltis was a conventional 4WD, but featured all-independent suspension and a long-stroke 1.7 litre version of the VW Passat/Audi 80 engine. The gearbox/transaxle was also derived from the Passat/80 front wheel drive cars, modified by way of an open propeller shaft to the rear axle. Shortly after the release of the Iltis at the Amsterdam Motor Show in 1979, a civilian version became available, with a peak power output of 53 kW and an unladen weight of 1,550 kg.

During the development of the Iltis, one of the senior Audi project managers, Walter Treser, secretly modified the Iltis four-wheel drive components to fit an Audi 80 sedan, without being given authority to do so. After his experience in racing and rallying, Treser was convinced that a performance-oriented road car would benefit greatly from four-wheel drive, and so used his own initiative by testing and improving on his secret project. By 1977 he was confident enough with his development to offer the Audi Chairman, Gottlieb Strobl, a drive of the vehicle. The Chairman was impressed, and the project was then officially approved.

As for Treser's motivation for conceiving a four-wheel drive road car, there was no thought at this point of using the vehicle in competition, simply because the Appendix J homologation regulations stipulated that only two-wheel drive was permissible. With some discreet lobbying by the Germans, the FIA (La Federation Internationale des Automobiles) changed this rule in 1979 by permitting the use of four-wheel drive. Thus the Audi quattro development team could include in their brief not only the development of a high-performance road car but also one that could be competitive in world-class rallying.

The basis of the quattro bodyshell was the Audi 80 platform, introduced in sedan form in 1978. The Audi coupe, a two-door fastback derived from the sedan, was due for release in September 1980. It was this body that the quattro development team used for their car. Subtle guard flares to accommodate wider wheels, and a tail skirt were the only visual differences. The floorpan was modified to accept the quattro drivetrain, and the front wishbones were reversed for the rear suspension, which also used the MacPherson struts from the front.

To be competitive in Appendix J rallying the quattro would need more power than the rally favourites, which were far lighter cars. The weighty quattro would need not only the five-cylinder engine released in 1976 in the 100, but turbocharging as well. The normally aspirated 2144cc 100 motor was good for not much more than 136 bhp. As the standard for competitive front runners in international rallies was around 250-270 bhp, this motor as it was, was not good enough. However by installing a KKK turbocharger and intercooler, with Bosch or Pierburg fuel injection, the rally version of the five-cylinder turbo could develop 320-330 bhp at 6500 rpm.

The quattro was not a car designed in isolation. The body was a close derivative of the Audi Coupe. The motor and gearbox were derived from the 200 turbo. The rear suspension and subframe was from the front of the 200 and of course the four-wheel drive components from the Iltis. What made the quattro so special was how extraordinarily well it all came together. This car had the engine and suspension as good as any other sports coupe, but with one significant advantage - four-wheel drive transmission. With this came the discovery that the friction involved in powering two extra wheels was negligible - in fact the four-wheel drive cars proved slightly more economical than the two-wheel drive cars.

The traction the quattro provided meant that one had to get used to driving it. The press fleet cars suffered an unusually high accident rate, and in the first six months of quattro production demand was unusually high for replacement front spoilers and radiators. It was thought at the time that this was due to the unrivalled adhesion of the quattro, where journalists and even private owners were becoming overconfident. While perhaps a trap for the unwary, the quattro had achieved the ultimate in international rallying in 1984 - seven wins in ten world title events, Audi taking out the World Rally Championship of Makes, and Blomqvist and Cederberg winning the World Rally Driver’s Championship with their quattro.

The Audi quattro was not purely a convenient image-maker for Audi. The development work of Piech also provided for the use of the quattro drivetrain in other vehicles. Hence the Audi 90 quattro, the Coupe quattro and the 200 quattro were soon on sale, quickly attracting buyers particularly in inclement countries where four-wheel drive is a must. Before these Audis, the choice was limited strictly to Range-Rover type vehicles.

The More Things Change...

By Steve Carter

June 1993

They say there is nothing new under the sun, and the same can be applied to cars.

For example Hemi heads, which Chrysler made such a big noise about in the '70s on their Valiants. Hemi heads, or hemispherical combustion chambers, have been about since almost the dawn of the automotive age.

Also the G60 supercharger fitted to the VW Corrado, Passat III and Golf II is actually an old design, which previously was unable to be manufactured successfully - until VW worked out a method to accurately machine components to extremely high tolerances of fit.

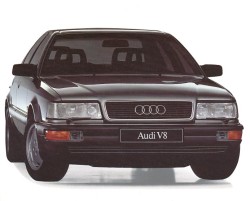

So if you may or may not be aware that the new Audi V8 has a different style of front disc brake system; different that is, but not new. This system uses the same principle as used on the Maico after-market disc brake system for early Beetles.

For those of you whom are not familiar with either system, I will enlighten you. Imagine an LP record held between your thumb and fingers, and you have the conventional disc brake. The record is the disc, your hand is the calliper and your fingers the brake pads.

It is a system that works well, but with limitations. To increase braking power you need to increase the disc size for greater leverage or pad area, and that is where problems arise.

To increase disc size, remembering that the overall diameter of the disc and calliper is a great deal bigger than the disc alone, so you need larger diameter wheels; not always a feasible option. To increase the pad area would add to complexity, not to mention unsprung weight.

Now imagine a doughnut similar in outside diameter to the LP record, but with a much larger inside hole. Put your hand into the hole of the doughnut and grab the doughnut ‘disc’ from the inside. Put the LP record and and LP-sized doughnut side by side and you will immediately see that the latter, with its internal calliper, takes up far less space. Apply this principle to a real car with doughnut-shaped discs with internal callipers, and there can be a considerable increase in disc diameter (and remember the advantage of extra leverage), without the need to increase wheel diameter.

This brilliant old idea was jointly developed by Audi and brake manufacturer Alfred Teves for the new Audi V8 flagship. The V8 has ventilated discs front and rear.

Audi has for some time experimented with various brake systems, including angled discs in a bid to increase braking without resorting to over-size tyres and rims.

Audi engineers discovered that the brake area could be increased by 20% using this system, and under repeated fade tests it was found that the ‘doughnut’ discs had a 150 degree Celsius reduction in maximum temperature than the old style system. Another advantage is that because the calliper is mounted onto the stub axle closer to the wheel centre, the brakes have more feel and less power assistance is needed.

My Next-Door Neighbour's Audi (and Mine)

By Rod Young

September 1993

This month I’m reporting on a car belonging to my neighbour.

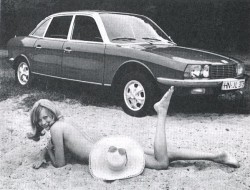

It would have been a shame to see such a nice car, a dark blue 1979 Audi 100 CD, dismantled in the name of spare parts, so it was snapped up for a price I'm not telling you. The car immediately won the approval of my neighbour’s six-year-old son, because it has little lights in the back doors that shine down onto the ashtrays. Also, the central locking almost nearly worked, which is not one of those things to be expected. So it got the thumbs up.

It had had a recent spray job and surprisingly little rust, and what there was of that is currently undergoing excision. Like with so many other 100s of its vintage, rust is bubbling up from around the scuttle panel; that’s the one around the base of the windscreen (if anyone knows why it's called a ‘scuttle’ please let me know. Probably nautical in origin). I think the clips that hold the chrome trim in, which themselves rust away, are the catalyst for these attacks. The windscreen is bonded in with urethane. Audi was the first European manufacturer to use this process, and it has some advantages, such as improving the overall body stiffness and eliminating a rusty floorpan due to water leaks from that area. Unfortunately, on my next-door neighbour's Audi, the rust goes too close to the windscreen to allow easy repair and the screen must be removed. The urethane gets very hard over the years and it did not want to give, so the screen, along with the removal tool, did not survive the removal process.

At least as much money as the car originally cost has been spent on it, since there are plans to make this car last. First it was the front end. The front tyres were scrubbing out; the car veered to the left under braking and mysterious noises emanated from the general strut area. The wheel alignment man advised not investing the $35 because it needed new bushes. Investigation showed that all the rubber bushes for the suspension subframe, control arms, sway bar and strut lop mountings were variously split, squashed or mutilated, so fairly serious replacement was in order. The genuine Audi parts were quite dear (31% of the value of a blue 1979 Audi 100), but made the world of difference after installation, expertly done by Adrian Muller. We've since found out that these parts are available in urethane from AP Spares in Riverstone, and Nolan in Thornleigh. Usually the gearbox mounts go the same way, apparently, but they were OK on this car.

Next on the agenda was to investigate why the compression was low in one cylinder and the idle so rough as to rattle your teeth. Tony, the amiable Austrian at AP Spares, pulled the head off and replaced five exhaust valves, amongst other things such as an exhaust manifold, welsh plugs and hoses. Tony will tell you any day of the week that Audi and VW water cooled engines are far superior to BMW engines, something he also knows a thing or two about. He found that someone in the past had rather inexpertly installed a high lift cam. After the head went back on, we couldn’t believe the performance of this car. 100s were never thought of as a quick car and were criticised as such by the motoring magazines at the time, but this thing fair rockets along.

Now that it s going more than half decently, it's a very rewarding car to drive. Smooth ride, effortless power, light controls, and great long distance cruising ability. The technology and appearance are still far from dated; it's easier to justify driving this car to your friends than, say, a 1979 Toyota Crown or Nissan 280C. People even compliment you on your nice car, and are genuinely intrigued when they fail to answer correctly the question about how many cylinders it has. And it doesn't take more than a week to get used to the massive steering wheel and sitting on a cushion, even with the seat height adjustment up to the max. One of these days I’ll get the central locking right.

I've always thought it would be great to own a series 3 Audi 100, even though that's not really what they're called, but you know the one - built 1983-1990, great aerodynamic shape, flush windows, 5-cylinder engine. Such cars were always for the better-off class of people, I thought; I would never be in the position of owning something so desirable.

My previous method of conveyance was as far removed from the luxury and comfort of this car as you could get - a 1973 Type 3 station wagon. It was always an unfinished project, with highly idiosyncratic modifications that I won’t go into. Nobody ever wanted to get into that car with me, and I don't blame them. It was ugly, noisy, uncarpeted and smelt bad. Ashamed as I was of the Type 3, it was always my intention to finish it one day. This was the cross I had to bear, I thought, but then the pressure of getting a pink slip for it when registration was already overdue after an overseas trip was too much, and the salvation of a seductive replacement in the form of an Audi 100 came along.

I had already been driving a borrowed, earlier model 100 and I appreciated its virtues. The prospective replacement belonged to well known club member Ed Garcia, and we all know how he looks after his cars. The price was right, thanks to depreciation through lack of appreciation of Audis on the Australian market.

So it was with some surprise and pleasure that I found myself owning this car. What a contrast to the foul Type 3!

The first thing I noticed, something I still notice every day with never ceasing amazement, is that the aerodynamics work. Lift off the throttle and it cruises along just as quickly. Where other cars are still on the throttle approaching a corner, I'm trying to slow this car down. Comparison is valid because I’m used to the previous model 100, which has the same basic engine, gearbox and suspension; all the differences are in the body.

I was plagued for a long while by a leaking power-steering pump. It wouldn’t have been so bad if it were ordinary ATK, but Audi sees fit to use their own purpose-designed fluid, and when it costs around $30 a litre, a leak is a serious proposition. The pump not only powers the steering but the brakes, which removes a bulky vacuum servo from the engine compartment.

I tried everything I knew to plug the leaks, which were coming from around some pressed-in plugs. Araldite; solder; peening with a centre punch. Eventually a replacement was found, oh joy, because I had gone through five bottles of the expensive stuff by that stage.

The only other thing to cause me ongoing angst is the climate control. According to the owners manual, it’s normally only fitted to the 200T, a much more expensive car. It must have been specified particularly for the Australian market. The unit is made by AC Delco in the USA. The designers have been too clever by half. Its sophistication sort of matches the space shuttle (you know what happened to that); three electronic units, numerous sensors and a mass of wiring. Apart from the fact that some parts of it don’t work, such as getting air to the dash-level vents, it just can’t know that I'm feeling warm or hot in the same way as I can. To operate it, you dial in a target temperature. The electronics supposedly warm up or cool down the interior until the desired temperature is reached, then maintain it. But driver and passenger have no control over which vents or fan speed. I've gone to the trouble of fitting a fan switch from a Golf and will soon install switches to control the air outlets. OK chaps, your next design needs to have remote temperature sensors embedded under the skin of the passengers, dealer installed. These transducers should measure skin galvanic response and transmit a signal to another control unit (no room behind the dash - try under the seat), which automatically opens a window.

As far as long-term longevity of this car is concerned, I'm optimistic. There isn’t one speck of rust on it, even though it isn't one of the fully galvanised models introduced in 1985. I’ll have to do something about the cracked dashboard: a sore point for VW/Audis. I’ll be changing to silicone brake fluid, renewing some front-end bushes and replacing the water cooled ATK cooler with an air cooled one, just in case, as they are known to fail, with horrendous results for the transmission.

By the way, I’ll soon be wrecking a Type 3.

Audi wins its first Australian Motorsport title

By Steve Carter

December 1996

Brad Jones and the ORIX Audi Sport Australia team have given the German car maker its first ever Australian motorsport title with a clean sweep in the 1996 BOC Gases Australian Super Touring Championship, winning the drivers’, manufacturers' and team prizes.

But it was no easy fight for the Albury-based team, with the battle for victory going right down to the last race at the last round at Oran Park over the weekend (Saturday 9 November 1996) with Jones having to win both races to take the drivers' title. Team mate and Bathurst winner, Greg Murphy, also had to finish both races to enable Audi to add the manufacturers' and team awards to its 1996 account.

The 1996 Super Touring season opened with two non-Championship events, the first in support of the Melbourne Grand Prix and the second at the Indycar Grand Prix at Surfers Paradise. Fresh out of the box, the ORIX Audi A4 quattros put in an impressive performance at the Melbourne Grand Prix, but not enough to overcome the Diet Coke BMW team.

Paul Morris and Geoff Brabham had received their new cars before the Adelaide Grand Prix, and an off season of testing under Australian conditions provided two convincing wins for BMW.

By the time the Super Touring circus arrived at Surfers Paradise, the ORIX Audi Sport Team had got some testing under its belt and was ready for a good performance at the circuit where it had its best performance in 1995. It was not to be, thanks to a combination of poor event organisation and a massive accident for Brad Jones that did more to prove the Audi A4 quattro’s inherent safety, if not its racing-winning ability.

So by the time the BOC Gases Australian Super Touring Championship opened its doors for the first time at Sydney's Amaroo Park in May, the ORIX Audi A4 quattro had shown a great deal of potential but it had yet to take the chequered flag in Australia. That all changed at Amaroo Park. Jones and Murphy dominated totally, with the red and blue ORIX Audi A4 quattros leaving everyone else in their wake for a walkover one-two victory.

But by the time the team arrived at Lakeside, the spectre of a weight penalty levied on the highly successful Audi teams abroad began to hang over the team. Jones and Murphy looked as if they were on the way to another dominant win when Jones’ engine decided it had had enough in race one and the race switched to the paddock, with the ORIX Audi Sport Australia team battling to repair the Audi A4 quattro in time for the next race. A new engine was slotted into place in just 53 minutes and its running-in period was flag to flag win for Jones.

The ORIX Audi Sport Australia team returned to Amaroo Park with an unwelcome guest in its cars, a 30 kg lead weight strapped to the body to bring the Audi's performance back in line with the other competitors. It didn't stop Jones winning both races. Murphy had his share of problems, though, with a new engine slotted into his car replaced a failed unit that kept him out of practice and which left him in fifth place in race one.

Greg Murphy's first win came at Mallala, following Jones leaving the track on another car's oil and narrowly missing Morris who was flying backwards. The talented New Zealander almost got his second win in race two: Brad Jones, who had led for the whole race, miscounted and slowed down a lap early for the finish. After seeing off an opportunist move by Geoff Brabham, Greg let Brad past metres before the finish. “The most embarrassing moment of my career,” Brad Jones called it!

Winton, the Albury-based team's home track, should have been a walkover for the team, but it turned into the worst event of the season. A combination of a new surface on the track and tyres that could not cope with it had Jones and Murphy sideways so often it was more like a rally. To compound this, Murphy went out in an accident in the race.

Phillip Island was better, but not much. Following a clockwork one-two in race one, Jones and Murphy were ready for a repeat in race two, until a puncture sent Jones into the pits. A second tyre failed, thanks to damaged bodywork, and Jones was out of the race. Murphy then drove to his second win but not without a lot of pain. The power steering failed in his car near the start and the battle to finish left him slumped over the wheel of his car shattered with exhaustion metres after talking the chequered flag.

Lakeside's second round, and the penultimate round of the series, saw BMW equipped with two brand new BMW 318i 1996 cars to Audi’s 1995 models, still with the 30 kg ballast. This gave the Diet Coke team a decisive advantage, giving Murphy two mid-field finishes, while Jones, who finished third in race one, and spending race two battling to recover from a start line accident with a resultant 12 minute driveshaft and rear suspension swap to keep him in the race.

So, far from going into the last round of the series at Oran Park in the totally dominant position predicted by the media at the start of the season, the organisers, TOCA, had ensured that the final round was a fitting nail biter for what has proven to a uniquely exciting race series.

Super Touring is now positioned, with its fourth Australian season in 1997, to provide motorsport fans with a level of competitive motorsport action that will keep them glued to their seats at the race track and in front of the TV.

NSU Ro80

By Tony Davis

June 1998

Car of the Decade. Machine of the Future. The most significant automobile since WWII. There seemed no praise too lavish for the stunning NSU Ro80, unveiled at the Frankfurt Auto Show in Germany in September 1967, and released for sale in Australia from mid-1969.

The front-drive, wedge-shaped exercise in advanced aerodynamics and improved packaging efficiency was truly revolutionary, and set the tone for the so-called aero cars of the 1980s.

Furthermore, the NSU newcomer was fitted with a Wankel rotary, the smooth, compact and powerful miracle of design that was poised to oust the standard reciprocating engine from its smug position of power.

The car received worldwide acclaim. Twelve international motoring journalists voted the Ro80 "1967 Car Of The Year", the first time a German model had captured the coveted award. The English magazine Car voted the Ro80 the "most significant technical development of the year".

Yes, the Ro80 was a once-in-a-generation car, changing all that followed. The pity was that it sent its manufacturer broke and left tens of thousands of owners enormously unhappy.

The Ro80's twin rotor engine had a capacity of only 995cc, yet developed a huge 96 kW. That was the good news. NSU had even developed the Ro80's engine further into the marine Ro135 derivation, developing 105 kW. 16 licence partners took out manufacturing agreements on the Wankel engine design, including Fichtel & Sachs, Toyo Kogyu (Mazda) and Yanmar, and these manufacturers between them sold an additional 33,600 rotary engines in 1969 alone. This brought NSU much licence income, though still not enough to pay for the enormous development costs.

The bad news went beyond the unfortunate decision to name the engine after its designer, Felix Wankel. NSU was in financial trouble and the Ro80 had been rushed to market before the engineer's considerable concerns about mechanical durability had been fully addressed.

In Australia the Ro80 caused great excitement; athough at $6,400 it was priced against Jaguars, Mercedes Benz, Rovers and BMWs. Sales were not especially brisk in the fairly conservative luxury market.

The Australian NSU importers (LNC Industries, who owned Volkswagen Australia), tried to counter Wankel anxiety with an extended warranty - which just added to the huge bills it faced. The engine seals were made of a soft iron alloy and failed to do the one thing they were supposed to, namely seal the chambers created by the triangular rotor within the epitrochoidal (oddly shaped) housing. Engine failure at 16,000km and less was common.

Around the world, NSU replaced thousands of engines free - alas, with more Ro80 engines. NSU refused to accept full responsibility for the engines' premature failure, as they apportioned much blame on poor maintenance and "abuse of the free-revving nature of the Wankel engine."

It was a particular shame because the Ro80 had so many other virtues. Consider the roomy cabin with long, flat floor, the clever clutchless semi-automatic transmission, the almost eerie quietness and smoothness, and the 175 km/h top speed.

In late 1969, the Volkswagenwerk took over the financially challenged (ie. bankrupt!) NSU company, and merged them with their Audi division. Ro80 production continued for another eight years, although Australian sales were wound up in mid-1973.

37,400 Ro80s were built at Audi/NSU/Auto Union's Neckarsulm plant by the time the model was finally wound up in September 1977, just after the one millionth Audi (since 1965) was completed. It was the last production vehicle to carry the famous NSU name.

Many former NSU engineers stayed on, and later helped to refine the Ro80 concept in a completely new design for Audi. The conventionally powered (but otherwise surprisingly similar) Audi 100CS of 1982 finally realised the promise of the brilliant but fatally flawed NSU Ro80.

A Fast Lap around Bathurst

By Brad Jones

September 1998

Bathurst is one of the most demanding circuits in Australia, and because we only really race here once a year, you only have one opportunity for success. This is what it is like to drive around the circuit in the current Audi A4 touring race car.

The fast lap begins at Pit Straight, which is slightly uphill. By the end of the straight you have reached 180 km/h and you are in fourth gear. You brake hard, go back to second and turn hard left into Hell Corner (now commonly, and boringly, called ‘Turn One’). This is one of the track’s most critical corners because of the long haul up Mountain Straight. A mistake here means you have to carry it all the way to Griffins Bend. If you are down 500 revs coming out of Hell Corner, you will still be down 500 revs when you get to Griffins Bend. Also known as GTX Bend, Griffins Bend at the top of Mountain Straight is a right-hander and requires precise braking.

Back to third gear and because the road has a slight off camber, you can float the car into the corner and get onto the accelerator early. It is important to keep plenty of speed on the car, as there is steep climb to the Cutting. You get up to 165 km/h on the way up to the Cutting, and it is a very hard brake - the road is quite rough and undulating.

Back to second gear, concrete walls on either side of you. You are about to start the steepest climb on Mount Panorama. The road kinks to the right, over a bump and you quickly move into third gear. Running along the fence, you grab fourth gear as you turn right and head into Reid Park. Reid Park is where you come over a rise and then down through a dip. This is one of the toughest parts of the circuit. You run parallel with the concrete wall that is about 15 cm away from you, before you turn left at 190 km/h.

A slight lift of the throttle, turning right, there is a large curve on the inside of Reid Park that you need to get as close as possible to, but making sure that you don't hit it! If you do happen to hit the curb on the inside of the corner, it will throw you onto the curb at the exit of the corner and cost you valuable time. Then there is a slight rise into McPhillamy Park. This is one of the most famous corners of this track. Taken at 180 km/h with a change into fifth gear midway around the corner. Fifth gear takes you across Skyline at 210 km/h. You then start the rapid decent down the mountain.

Coming into the Esses you are usually in the middle of the road because it has takes you that long to get back over there. The first turn is to the left and it is blind! You can't see it coming, you have to brake very hard and you need to stay on the right hand side of the circuit. This is the part of the track that the Audi really excels. It is usually flat on the throttle just before you get airborne in the Dipper. Brake to settle the car down and then back on the throttle.

On the run down the hill you hit the rev-limiter then turn right and the car is really light. Like the corner coming up the hill, Forrest's Elbow is critical, as you really have to carry the speed down the hill. You hug the apex, and then you let the car drift right out as far as you can.

Conrod Straight is a little bit rough and the car tends to bounce around. You check your gauges and get on the radio and have a drink.

Going through the Chase is flat, you then get on the brakes after the dip. The car drifts across the road nicely through the left hander. You are flat through the right-hander out of the Chase and over the brow. There is a chink in the white line and I use this as a brake marker.

Like the first turn, the final one is a late apex corner so you get a clean run up over the finish line.

Hope you enjoyed your ride!

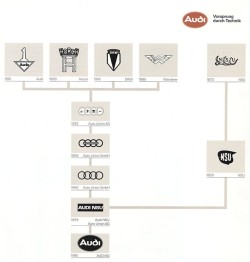

Audi – Historical Highlights

By Steve Carter

February 1999

After several years' employment at Benz & Cie, August Horch left his job and founded his own firm, August Horch & Cie, on 14 November 1899. He began as a repairer of automobiles. Routinely he installed Bosch coil ignitions with a linkage developed and patented by Horch himself. In 1901 for the first time Horch built his own car and tested it. Now he could introduce the features he had tried in vain to recommend when he worked for Benz - e.g. a shock-free engine whose two cylinders share a common combustion chamber, and a transmission interlocked with the differential and suspended from the frame behind the rear axle.

The following years saw the realisation of more of Horch's extraordinarily innovative ideas: for example, a Cardan-shaft power transmission and chromium-nickel steel heavy-duty gear wheels. Another significant innovation is an engine with overhead intake valves.

In 1905 Gertrud Eisemann caused a sensation. One of the first and fastest of Germany's woman motorcyclists, she ranked in fame second to none of the men then competing on two wheels. Frau Eisemann sets several motorcycle records. Among her long-distance triumphs is first place in the Eisenach-Berlin-Eisenach race, won on an NSU 2-hp. The manufacturer of this machine, NSU of Neckarsulm, was compiling an outstanding record of competition success, and remained a major world exporter until the outbreak of the First World War.

August Horch quit his own company in 1909, and founded a new one called August Horch Automobilwerke GmbH in Zwickau. Due to clashes with his previous company, the new company’s name was soon changed to Audi - the Latin for ‘Horch’. The word ‘Horch’ also means ‘Hark!’ or ‘Listen!’

Here is August Horch on his experience with early motor cars: “To start the engine you had to set the flywheel spinning; there was no question of cranking up the motor in those days; you just kept turning the flywheel until ignition occurred. It was hard work, but exciting.

“If you couldn't get the motor to ignite you had to go to the front of the car and play with the 'mixture control lever'. If you were lucky and the motor ignited straight off, you still had to run to the front and adjust the throttle valve lever till the engine began running smoothly. Then and only then - God willing - you could begin to set the vehicle in motion.

“You would get into the driver's seat and the car would start to move at a speed of about three to five km per hour. When she had reached maybe eight km/h, you would release the smaller gear and engage the larger one. From that point you might nudge her up to, say, a maximum of 18 km/h.”

Horch's first trucks were built before the First World War. Their earliest commercial vehicle was an ambulance, and the first heavy-duty vehicle was a chaff cutter built on a passenger car undercarriage. Some 8/24 chassis were made into delivery vans; others, fitted with 40- or 50-hp motors, became small trucks or light omnibuses. Motors of a mere 55 hp were used to power 3-ton trailer trucks.

In 1913 Horch himself, behind the wheel of an Audi, received first prize in a tortuous 2,250 km race on mountain roads - hence the car's name, ‘Der Alpensieger’ (Victor of the Alps). A four-cylinder vehicle, the ‘Type C’ was to become the best-known Horch model. The 14/35-hp engine boasted a crankshaft of completely new design, positioned 14 mm off axis in triple-babbitted red brass bearings.

The Audi team had picked up prizes in 1912, 1913 and 1914. The sedate trade journal ‘Motorwagen’ waxed enthusiastic: “The outcome, above all, was an amazing triumph for the German manufacturer Audi. Of five automobiles entered in the contest they brought all five through the finish line without a single point deducted.”

Meanwhile, at another German car company called Wanderer, the compact ‘Puppchen’ is at last produced for the market. Gruelling tests revealed the beauty of this new Wanderer concept. The four-cylinder, 12-hp engine and delicate, light body respond perfectly to high demands for performance and economy. So satisfied is everyone with the ‘Puppchen’ that the firm politely declines the offer of another small car model, designed by one Ettore Bugatti!

The basic, ever popular ‘Puppchen’ continued to be manufactured for fourteen years, before being replaced by a higher-performance model. Some changes were introduced after the First World War, such as overhead suspension of the two valves, and engine capacity increased to 1.3 litres. Although the designation ‘5/15 hp’ was retained, actual maximum performance is now 20 hp.

The 1921 Audi Type K was the direct successor to the famous ‘Alpensieger’. With its now standard left-hand drive, it made its debut at the Berlin Automobile Exposition. No longer cast in pairs, the cylinders now formed part of a grey cast-iron-headed aluminium cylinder block; the combustion chambers were also re-designed. Each combustion chamber was fitted with diagonally aligned valves, operated via the camshaft at the side of the crankcase with push rods and rockers. No fewer than three oil pumps provided lubrication of the motor. Cooling was achieved without a water pump, by the thermo-siphon principle, utilising a multi-speed, four-blade fan.

Between 1921 and 1923 engineering innovations came thick and fast. Audi was the first with left-hand drive, and a steering wheel that could be folded back. The Audi K included a tachometer as a standard feature and a ‘reserve’ lever setting on the fuel tank cap. Other innovations were the first Babbitt bearing-mounted crankshaft in a six-cylinder car and the first use of a suspension damper. At this time Audi was also a pioneer in the filtering of inlet air. Another innovation at this time is fluid-friction brakes. In 1927 the eight-cylinder Audi R made its first appearance. With its 100-hp motor it was capable of smooth acceleration directly from 8 km/h to speeds of up to 110 km/h. The firm's commitment to technical progress on every level receives visual expression in the new streamlined design of the Audi Type K.

The Horch 303, one of the first series production cars with an 8-cylinder in-line engine, appeared on the market in 1926 and soon becomes a symbol of excellence in the German automobile industry. To keep down the length of the car, the cylinders were cast in pairs in the cylinder block, with coolant only flowing between the pairs. With a capacity of 3.0 litres, the engine yields 60 hp. A total of eight gearwheels, working together, operated valves, lubrication, generator and coolant pump. A special model, the Horch 375, had rear springs 145 cm long consisting of 18 layers of chromium vanadium steel. This was also the first time a Horch car was designed with hydraulic vibration absorbers.

DKW was the biggest manufacturer of motorcycles in the world by 1928. Expertly co-ordinated management and a sharp eye for talent ensured product popularity. Among the talents discovered and employed were those of Hugo Ruppe from Leipzig, who contributed the two-stroke engine; Friedrich Miinz of Stuttgart, who developed the Dynastart, a combination generator and starter; Dr Herbert Venediger, the first to study the two-stroke engine systematically; and Hermann Weber, the chief constructor at Zschopau, whose motorcycle designs were among the best on the market.

All attention was riveted on Horch's sports convertible, first shown at the Paris Automobile Salon in 1931. Under her yellow bonnet the car displayed a new wonder: a 12-cylinder, V-type engine with 6-litre capacity. To meet the highest demands in performance, the seven-bearing-mounted crankshaft was furnished with twelve balancing weights with a suspension damper at the front end. A special duct system provided for the lubrication of the pistons, and the valve lifters were hydraulically operated.

Also in 1931, DKW introduced the F1 at the Berlin Automobile Exposition. It was the prototype of the first mass-produced small car with a transverse engine, front-wheel drive, and independent wheel suspension. Its plywood chassis, covered in imitation-leather, took only six weeks to develop.

These four car makers joined up together in 1932. The four-ring symbol was adopted, representing the linking together of Wanderer, Horch, DKW, and Audi in the AUTO UNION in June 29th 1932. Soon it became Germany's second largest manufacturer of motor vehicles. The new trademark symbolised the unbreakable union formed by the four companies.

It took AUTO UNION about three years to co¬ordinate its various types, models and policies into a unified profile. The result appeared in the standardisation of chassis and undercarriage, and the common use of certain basic parts in construction. Economy was now a paramount consideration; the greatest pressure was for cost reduction. A more streamlined chassis, patented by Paul Jaray, was introduced. It underwent extensive testing in the wind tunnel.

This was how the motoring magazine ‘Automobiltechnische Zeitung’ reacted to some of the new models: “As the German AUTO UNION makes its debut in Paris, Horch dominates the entrance to the salon with three machines, all prize exhibits with distinctive bodies. One of them is a short, light-green sport convertible with a 4.5-litre engine; another is a Silberfisch convertible with a 5-litre engine; the third is a dark brown 12-cylinder limousine with double downdraught carburettor, intake silencer, overdrive synchromesh gear, compressed-air hydraulic power brake, fresh-air heating, illuminated map table, four-wheel jack, anti-theft installation, etc. What a lot of cunning, outrageous devices! This apparently extensive Horch product line proves you can turn out a broad range of products with economically limited - but cunningly deployed - means.”

Hans Stuck set a world record at the Avus in 1934 with the new AUTO UNION racer. The construction was by Dr Ferdinand Porsche. For the first time in a racing car, the engine (16 cylinders) was situated behind the driver, anticipating by several decades a principle of construction commonly observed today.

The first soundly based, empirical crash test programme (incidentally, satisfying modern criteria) was begun in Germany by the Central Test Department of AUTO UNION in Chemnitz in 1937. At the time DKW had introduced what was to be its last series of models, some of which had chassis constructed of synthetic materials. In such tests head-on and side-on collisions and rollover are simulated. Over 3,000 national and international patents attest to innovations introduced by the Saxony automakers, as a result of these experiments.

By 1939 AUTO UNION offered a vast array of motor vehicles, from motorcycles to luxury limousines. Germany's second largest automobile manufacturer now produced 25% of all private cars and 35% of all registered motorcycles.

As a major supplier of motor vehicles to State administration and the armed forces, AUTO UNION'S government contracts, by 1937-1938, exceeded the total production of all Audi, Horch, DKW and Wanderer private vehicles. Horch and Wanderer military vehicles were reliable workhorses for the German forces throughout the war, as were DKW and NSU motorcycles.

The AUTO UNION works were in the Eastern, Russian-controlled sector of Germany. After the war, pursuant to orders of the SMAD (Soviet Military Administration in Germany), the works in Chemnitz was dismantled and expropriated by the occupying power. Most of the machinery was shipped to the USSR. In 1948 the AUTO UNION name was struck from the Commercial Register. However, pre-war DKW designs were used by the Russians to produce the Trabant, which was built in the old Zwickau works until the 1990s.

In the West, to help cope with the post-war transport shortage, AUTO UNION was resurrected in Ingolstadt, Bavaria, in 1949 and began production on the F89L delivery van, the first post-war German vehicle with a forward control chassis. This DKW pick-up van was exhibited at the 1949 Spring Fair in Hannover. It had a two-stroke motor. By the end of the year a total of 504 F89L pick-ups and 500 DKW RT 125/W motorcycles had come out of the factory. The ‘W’ in the name stood for ‘West’, to distinguish these motorcycles from those of the same type built in Zschopau, in the Russian Zone.

The first new DKW passenger car, the F89P, rolled off the line at the company's new Dusseldorf plant in 1950. As in former times, this vehicle was presented under the title, ‘Meisterklasse’, a term which expressed the combination of pre-war chassis unit with the two-stroke motor (now boosted to 23 hp) (F8), and body (F9). This car was offered as a limousine, four-seater convertible (Karmann), two-seater convertible, or coupe (Hebmuller). A station wagon was also marketed, under the name of ‘Universal’, with a body at first of wood and steel, then all steel.

In 1956 Meier, Theiler, Barbay and Ahrens set world long distance records with the plastic-chassis DKW on the track at Monza. In the 1100cc and-under class, races covered 4,000 miles in 48 hours and 5,000 miles in 72 hours. Afterwards, the similarly designed and appropriately named DKW ‘Monza’ was produced as a limited series of approx. 230 cars. The decade 1954-64, in which AUTO UNION was a regular participant in Touring Car competitions, saw this popular DKW chalk up an unprecedented series of victories: over 100 championships, 150 victories in overall classification and some 2,500 class titles won by DKW drivers.

In 1957 a new car, the NSU ‘Prinz’, arrives on the market in three versions, with three different engines and three different sets of standard equipment. The world's first mass-produced car with a Wankel combustion engine, the NSU Wankel Spider, is shown at the Frankfurt IAA (International Exposition of Automobiles) in 1963. Externally, the new model looks like the familiar Sport-Prinz. But beneath its rear bonnet lies a 50-hp rotary engine capable of propelling it to speeds of up to 150 km/h.

The new Spider boasted an entirely new chassis with up-to-date styling, in sharp contrast to the rounded forms of the previous decade. The overhead-valve, air-cooled 30-hp engine retained its position in the rear. The car proved so popular that by 1963 74,000 are sold.

In 1958 everyone was talking about the elegant 1000 Sp - the dream car with fins, available as either roadster or coupe. In designing it, Chief stylist Josef Dienst drew heavily on American motifs of the period. “One day in the autumn of 1956, Direktor Werner came up to me and said, in his Americanised German: ‘I want you to design a sports car that looks like a bomb!’” And so was born that cool classic of the fifties, the 1000 Sp.

AUTO UNION came under Daimler-Benz ownership in 1958, who took over their Dusseldorf factory. Daimler-Benz constructed a new DKW plant at Ingolstadt in exchange. DKW introduced two new models, the Munga light 4WD vehicle, and a new small car called the DKW Junior, in 1959. The Munga was popular with the armies of Germany and other NATO countries, particularly Holland, and remained in production until 1968. The Junior was also popular, with sedan, wagon and roadster versions produced, all powered by the familiar DKW 3-cylinder 2-stroke engine.

In 1965 the Volkswagenwerk purchased the AUTO UNION business from Daimler-Benz, and production of two-stroke DKWs was quickly phased out. The last one was the F102, which was then upgraded and fitted with a Daimler-Benz engine. Volkswagen decided to retire the ‘DKW’ name, and sold the new model, the F103, as an ‘Audi’. This was the first time the ‘Audi’ name had been used since the early 1940s. VW also assembled Beetles in the AUTO UNION Ingolstadt factory for a short time, but the new Audis were so popular that Beetle assembly was soon terminated. The new Audi range soon consisted of the Audi 60, 75, 80, Super 90 and 100 models.

In 1969 the Volkswagenwerk also purchased the NSU company, which had already introduced the space-age Ro80 Wankel sedan but was struggling financially. VW merged NSU with their Audi subsidiary to create ‘Audi-NSU-Auto Union GmbH’. VW produced the conventional engined NSU K70 as the first watercooled Volkswagen in 1970, but it was not a success. When the Ro80 was discontinued in 1976, the NSU name was retired.

VW’s Audi division has since been the backbone of the modern VW concern. The Audi 80 formed the basis of the VW Passat, and its engine was also used in the Golf and Scirocco. The Audi 50 became the VW Polo. In 1985 the Auto Union division was renamed to ‘Audi AG’, ending the ‘Auto Union’ and ‘NSU’ names, but the four rings on the grille of every modern Audi is a reminder of the company’s long and interesting history.

Jones makes history for Audi

By Steve Carter

July 1999

Works Audi driver Brad Jones created history for the German manufacturer Audi at Winton Raceway in Victoria today, with a dramatic victory in round four of the BOC Gases Australian Super Touring Championship.

Jones' win in the first of the three races was the first victory by a front-drive Audi A4 in a national Super Touring championship worldwide. Audi's previous success in the category, including championship titles by Jones in Australia in 1996 and 1998, had been with the Audi A4 quattro.

For Jones, it was also his first championship win of 1999. The 39-year-old from Albury took the chequered flag in the eight-lap event in 21 min 19.60 sec, finishing 1.69 seconds clear of championship leader Jim Richards in a factory Volvo Racing S40, and Queensland's Paul Morris in a NEMO Racing BMW 320. Morris was second to finish, but was penalised 1 second after making contact with Richards' Volvo in a passing move. The penalty lifted Richards to second place, and relegated Morris to third.

The race, originally scheduled for 10 laps, was stopped on the opening lap following confusion over whether warm-up laps should have been held after a delayed start. Just moments after the re-start there was an incident that eliminated the works Volvo of Mark Adderton, and Independents Cup driver Tony Newman in a TC Motorsport Peugeot 406. Dean Canto, driving a Ford Mondeo and Anthony Robson in a Honda Accord were also involved in the incident, but were able to continue driving. Volvo Australia Motorsport Manager John Cotter estimated damage to Adderton's car was $30,000.

Morris won the second race over 14 laps in 20 mins 30.52 sec after leading from start to finish. Jones, was second, followed by Audi Sport Australia teammate Matthew Coleman. John Henderson was fourth, and the leading Independents Cup driver. Richards was forced out of the race after his Volvo suffered wheel damage on the opening lap.

In the final race, over 20 laps, Morris led the opening stages from Richards. On lap eight both drivers made their compulsory pit stops to change two wheels, and Richards resumed racing ahead of the BMW. Morris pressed Richards, until spinning in the closing laps. Richards then cruised to win in 29 min 42.67 sec, finishing 10 seconds clear of Morris, who was followed by Coleman and Jones.

Morris scored most points for the round, 37. Richards now leads the championship with 107 points, Morris is second on 106, and Jones third on 83. Volvo retained the lead in the manufacturers championship with 117 points, followed by Audi on 114. Signature Security Systems Ford Mondeo driver Peter Hills leads the Independents Cup with 118 points, with team-mate Canto second on 63.

“It's great to win again, especially in the front-wheel-drive Audi,” said Brad Jones after the first race. “It shows the car can be a winner, and it also proves how hard we've worked. The start of the first race was a nightmare. I had turned the engine off, and the next thing I saw the race was about to start so I put it in gear and took off. I made a terrible start. After the re-start I got away in front and everything fell into place.”

Peugeots are better than Audis!

By Bastin Moreau

February 2001

First, let me introduce myself. I'm 28 years old and I'm French. I'd like to comment on Mr Matthews's report about Audis at Pikes Peak, that I found on your Australian VW Club website (see above)

He says that “...Peugeot and Vatanen only beat Walter Rohrl’s time by 0.63 seconds, over a distance of nearly 20 km. That’s only a 0.097% improvement. Compare that with the huge leaps by which Audi would improve each year...”.

It seems that Mr Matthews has forgotten that this year, it snowed in the last third of the track. It was completely wet and very slippy ! The first US cars which started the race, get out of the track !! Ari Vatanen and Peugeot has beaten Audi in very bad conditions.

So, Peugeot has beaten Audi in such conditions, it means that Audi and W. Rohrl were rather slow in good conditions.

Regards, B Moreau

And a response by Phil Matthews:

Hello from Australia, Bastin! Thanks for your comments on my article about Audis at Pikes Peak. As you know, the events I referred to happened a fair while ago, back in the 1980s when Audi ran the Group B rally quattros. These were modified further for Pikes Peak. After Walter Rohl's win in 1987, Audi did not compete at Pikes Peak again, and instead went touring car racing in the Trans Am circuit series.

So we haven't really been following what's been happening at Pikes Peak since. If there are no VWs or Audis competing, we don't care! I have no idea who competed this year, but I thought the most recent winners have been the Toyota Tacoma sport trucks - not real Toyotas, but hand-built frame race cars with carbon-fibre bodies.

The course record at the moment, in fact, is 10:04.06 by Rod Millen, set in 1994 in a custom-built, Toyota Celica Turbo AWD. The best time in 2000 (last year) was by Larry Ragland, 11:17.66 in a High Tech Truck & SUV.

As you say, if it did rain and snow the year that Ari Vatanen won (1988), then he did indeed drive very well. But I have seen 'Climb Dance' and the weather was actually fine and sunny, and Vatanen was shielding his eyes from sun glare. The point I was making, though, was that Audi did not compete in 1988, or afterwards, which was a pity. You are right that Audi was fractionally slower in 1987, but Walter Rohrl was unfamiliar with the track as he'd never driven it before. He did say that, if he were to try again, he could have been 25 seconds quicker in 1988. It is a great shame this never came about !

Thanks for enjoying our VW/Audi club website!

Audi Wins Le Mans 1-2-3

By Steve Carter

July 2000

The 2000 Le Mans 24 Hours has produced a dream result for Audi. A dominant victory was achieved in arguably the most difficult and demanding race in the world in front of a 200,000 plus crowd. After triumphs in world rallying and in touring car racing, Audi wrote a further chapter in to its already successful and illustrious motorsport history, with their first ever win at Le Mans.

In extremely hot weather conditions Audi proved their slogan - ‘Vorsprung durch Technik’ – Advancement Through Technology. The three Audi R8s were not only the fastest cars in 48-car field but also the most reliable for 24 hours.

Dr. Franz-Josef Paefgen, Chairman of the Board of Audi AG, remarked, “The foundations for victory were laid during the conception of this fascinating race car. Everyone who has contributed and worked on this project can really be proud, of course the team from Audi Sport, who have developed the R8, and Audi Sport Team Joest, who have done a perfect preparation of the race cars."

The three Audi R8s dictated the pace from the outset. In all practice sessions and almost during the entire race, Audi held the top three positions. With 368-laps, the winning car completed three more laps than last year's winner, a BMW. “We could not have done any better,”confirmed a delighted Dr. Wolfgang Ullrich, Audi's Head of Sport. “We had no technical problems at all.”

Rear sections on two of the Audi R8s had to be changed but only for safety reasons. “We did not want to take any risks,” added Dr.Ullrich. “Before this, Audi #9 had a spin while #7 had a puncture.”

The ultimate winner, the #8 Audi R8 driven by Frank Biela (Germany), Tom Kristensen (Denmark) and Emanuele Pirro (Italy), was delayed during the first half of the race by two punctures. Apart from that, the car was running like clockwork and was on top of the field from the 11th hour to the finish.

Frank Biela said, “The car was a dream especially considering that we did 24 hours at high speed and that we were fighting between ourselves.”

Despite Audi enjoying a big advantage, there were no team orders. Dr Ullrich explained, “We wanted to have a sporting fight. Our drivers had no team orders and they all showed during the race that they were true professionals and that they can handle a high-pressure situation. Everyone was clear that the success should be for Audi and because of that, to me, all of the drivers are winners.”

Behind Biela/Kristensen/Pirro, who had already won the Sebring 12 Hour race in America three months ago, Laurent Aiello (France), Allan McNish (Britain) and Stephane Ortelli (France) were second, with the similar Audi R8 of Christian Abt (Germany), Michele Alboreto (Italy) and Rinaldo Capello (Italy) coming home third.

Reinhold Joest, Director of Audi Sport Team Joest, confirmed, “This is an outstanding achievement, which makes history for Audi. Before us, only three other works teams achieved a 1-2-3 clean sweep at Le Mans.”

Audi’s historic Le Mans win is the first for the Volkswagen Group. However ‘cousin’ Porsche has won the event 16 times between 1971 and 1997, more than any other make. Ferrari was won nine times; Jaguar eight. The other German companies Mercedes and BMW have only won Le Mans once each.

Audi repeats its Le Mans triumph

By Chuck Macak

July 2001

For the second consecutive year, Audi has won the toughest motor race in the world: the Le Mans 24 Hours. After last year's searing heat, the Audi sports racing car now had to prove its qualities in torrential rain. “This success is even more valuable than last year’s,” declared Dr. Franz-Josef Paefgen, the Chairman of the Board of Audi AG. “To get both cars home in the top-two places in these extremely difficult conditions is anything but normal.”

The 69th running of the French endurance classic was at times similar to a speedboat race and will be remembered as a big rain battle. “During the entire race, the drivers had to be absolutely concentrated,” said Audi Head of Sport Dr Wolfgang Ullrich. Audi works driver Tom Kristensen echoed the sentiments of all his teammates by stating that it was “the toughest race I ever drove.”

For hours, rain was so relentless that drivers could only use half throttle on the long straights of the Le Mans circuit. It was also a particularly tough test for the cars’ chronology. Both the Infineon and Audi R8 cars, however, turned out to be water-proof and managed the 321 laps without major problems.

Both Infineon Audi R8 cars battled hard from start to finish for victory. In the course of the race, new Audi technology proved its worth: a V8 twin turbo engine with petrol direct injection (FSI) powered both works cars. This is a new invention in the Le Mans prototypes class (LMP).

In a repeat of last year's victory, Frank Biela, Tom Kristensen and Emanuele Pirro crossed the finishing line as winners. The sister car of Laurent Aiello, Rinaldo Capello and Christian Pescatori completed an Audi 1-2.

The two Audi customer teams Champion and Johansson were quick but had little luck: The two R8 cars in 2000-specification retired in the first part of the race.

With its second triumph at Le Mans, Audi continued its stunning series of victories in endurance racing. At Le Mans, the R8 celebrated its 13th consecutive victory in sports car racing. For almost a year, the successful sports racing car remains unbeaten.

Quotes after the race:

Frank Biela (#1): “To win Le Mans is difficult. To achieve it a second time is even more difficult. When we came here we knew we had a very competitive car but you have to make sure that everything is reliable and lasts for 24 hours. We made it. Very often we had to take decisions at the right moment. We were very good at this. The team did a great strategical job.”

Dr. Wolfgang Ullrich (Head of Audi Sport): “Due to the ever changing weather it was really a difficult and a very extreme race which put us under much more stress than last year. It was extremely important to react quickly and correctly in every situation and to avoid any risk in tyre choice. We were always on the safe side and we've never been using slicks at any cost even if it might have been possible at times. This was correct because in doing so, we simply avoided any errors.”

Race Results:

1. Biela/Kristensen/Pirro (Infineon Audi R8) 321 laps

2. Aiello/Capello/Pescatori (Infineon Audi R8) -1 laps

3. Wallace/Leitzinger/van de Poele (Bentley) -15 laps

4. Beretta/Wendlinger/Lamy (Chrysler) -23 laps

5. Deletraz/Fabre/Gene (Reynard-VW) -37 laps

6. Rosa/Babini/Drudi (Porsche) -38 laps

7. Jeannette/Dumas/Haezebrouck (Porsche) -39 laps

8. Fellows/O'Connell/Pruett (Chevrolet) -43 laps

9. Pemer/Neugarten/Srnith (Porsche) -46 laps

10. Chereau/Dumez/Goueslard (Porsche) -47 laps

Audi achieves Le Mans hat trick

By Steve Carter

July 2002

With a superb 1-2-3 in front of 220,000 spectators, Audi hs secured a special place in the history of the Le Mans 24 Hour race. Audi is only the fifth manufacturer to win the toughest car race in the world three times in a row - and the first to achieve this proper hat trick for nearly 20 years (Porsche was the last to do it with the 956 in the 1980s). The Audi works drivers Frank Biela, Tom Kristensen and Emanuele Pirro also wrote motor sport history: They are the first-ever driver squad to win Le Mans three times in a row.

The latest Audi triumph in the endurance classic, which has been held since 1923, was another demonstration of ‘Vorsprung durch Technik’ and an impressive combination of speed and reliability. Over the entire 5,120 km distance, the three Infineon Audi R8 sports cars, fitted with 455 kW FSI engines, were the fastest cars in the field. From the start, Audi led the race, never giving the lead away during the entire 24 hours.

From hour six onwards, all three works Audis were at the head of the field. And Tom Kristensen shattered the lap record by almost four seconds. In total, the winning car covered 375 laps -seven more compared to the record drive in 2000.

Despite the stunning 1-2-3, the 70th running of the Le Mans 24 Hour race was anything but easy for the Audi squad. Warm and humid summer weather made it an enormous challenge for man and machine. The race also turned into a ‘tyre battle’, with unusually many punctures, which cost time and scarred the bodywork on the Audis. That the punctures caused no further serious consequences was also prevented by a system developed by Audi and tyre partner Michelin, which warns the driver of a loss of tyre pressure.

The punctures also had an influence on the final outcome of the three Audis. But as in the previous two years, Frank Biela, Tom Kristensen and Emanuele Pirro had the necessary slice of luck on their side again. They took the lead on Saturday evening, did not make a single mistake and so secured their historical third win at Le Mans.

Rinaldo Capello, Johnny Herbert and Christian Pescatori achieved second position just in front of the newcomers Michael Krumm, Philipp Peter and Marco Werner who made it to the podium in their very first race with the R8.

With the triple victory, Audi Sport Team Joest continues its amazing winning streak in the Le Mans 24 Hour race: Since the debut in 1999, the team always brought home every car. For the third time in a row, the cars of the Audi Sport Team Joest left all other competitors behind. In 2000 and 2002, Audi celebrated triple victories. During the ‘rain battle’ in last year's season, both entered R8 sportscars conquered the first two race positions.

The customer team Audi Sport Japan Team Goh scored a creditable achievement with seventh position despite an accident in qualifying and a radiator change during the race.

The road car customer already benefits from the FSI Power in the rear of the successful Infineon Audi R8 sportscars: The Le Mans proved direct petrol injection is also available for production cars. “The technology transfer between the racetrack and production cars is very intensive at Audi. The FSI technology is a very good example of that,” said Dr Martin Winterkorn, Chairman of the Board at Audi AG.

Results:

1. Biela/Kristensen/Pirro (Infineon Audi R8) 375 laps

2. Capello/Herbert/Pescatori (Infineon Audi R8) -1 lap

3. Krumm/Peter/Werner (Infineon Audi R8) - 3 laps

4. Wallace/Leitzinger/van de Poele (Bentley) -13 laps

5. Beretta/Lamy/Comas (Oreca-Judd) -16 laps

6. Sarrazin/Montagny/Minassian (Oreca-Judd) -16 laps

7. Ara/Dalmas/Katoh (Audi R8) -17 laps

8. Lammers/Hillebrand/Coronel (Dome-Judd) -24 laps

9. Taylor/Angelelli/Tinseau (Cadillac) - 30 laps

10. Boullion/Lagorce/Bourdais (Courage-Peugeot) - 32 laps

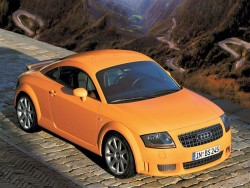

Audi TT 3.2

By Jamie Vondruska

May 2003

Audi's TT finally gets a pair. An extra pair of identical pistons, to be exact, and oh what a difference those little pistons make in an already fine coupe. More importantly though is the revolutionary racing-derived transmission connected to this engine, called Direct Shift Gearbox or DSG for short. The combination of the 3.2-litre VR6 and DSG may forever change the way you think about alternative transmissions.