Kombis T3-T4

A 4WD Syncro Drive

Volkswagen’s Seven-Seater Caravelle

The WBX 6

Not As The Maker Intended

Trakka Syncro-nisation

Kombi On Road To Big Van Assault

Kombi Makes a Comeback

Trakka Vans Attract The Fans

VW’s New T4 Bus

South African Muscle Bus

VW Is Back With A Vengeance

RHD T4 Caravelle

The New Volkswagen T4 Transporter

T4 Caravelle Road Test

Syncronicity - Bus mit Allradantrieb

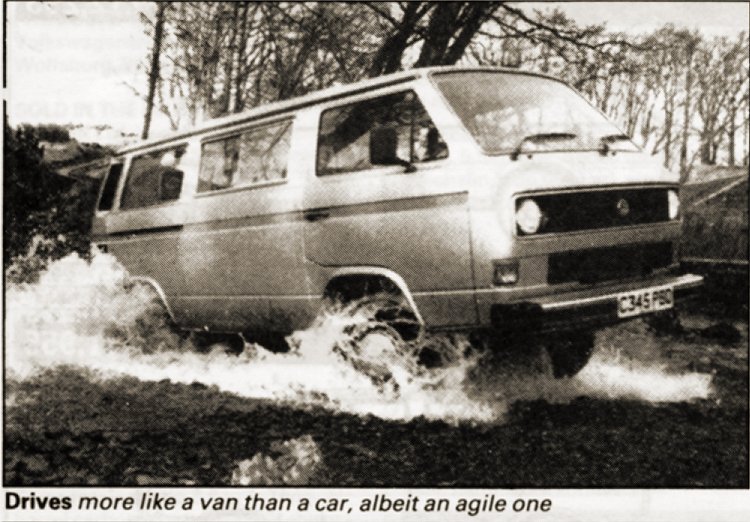

Syncro Kombis at the Range Rover Test Area

How does VW’s Syncro viscous coupling work?

Yes, But What On Earth Is Thixotrophy?

VW T3 Caravelle Syncro

VW T4 Caravelle

CT / CZ engines

High Mileage VW Shuttle

Series 3 Transporter Design Points

New T5 Transporter

VW Caravelle V6

Autobahn surprise

VW California set for Australia

A 4WD Syncro Drive

By Stephen Muller

December 1985

Last month at the general meeting I discussed a recent test drive of VW’s new toy…the 4WD Syncro Transporter. People who attended the motor show would have seen it on display at the VW stand. VW Australia decided to do a pre press release demo to VW dealers and selected Government bodies such as the Army, Water Resources Commission, Forestry Commission and so on.

The area chosen for the test drive (fun ride) was Duffy’s Forest, north of Sydney. Eric Haump was the VAG rep from Germany who was on a tour showing the Syncro to the Pacific basin. The engine on the 4x4 was a normal carburetted unit that looked very simple compared to the normal Aussie Transporters with fuel injection.

The basic 4x4 system is very simple, easy to service and is weight saving. Volkswagenwerk have used a version of the Fergusson fluid coupling system, manufactured and installed by the Austrian firm of Steyr Daimler Puch who have also produced the Haflinger and Pinzgauer vehicles. The suspension on the Syncro is stiffer and higher up than normal, and is also fitted with 16-inch wheels to raise the ground clearance further. The dash/controls setup is identical to the 2WD Transporter, the exception being vacuum-operated diff locks, front and rear, both being simple to operate. The transmission ratios have been altered with a crawler gear replacing first gear. This is identical in ratio to reverse.

The fuel tank is located in the rear of the bus again, as is the spare tyre.

Driving impressions? Well, simply amazing. On very rough terrain of slopes of 45 degrees the Syncro remained stable and VERY comfortable. The coil springs simply made you think it wasn’t rough. Naturally all the Govt people were amazed at the ride, expecting it to be similar to Jap 4WDs, but they soon had their opinions changed. Traction…it will move over the traditional rough 4WD terrain with ease, but you can’t expect it to crawl over logs and boulders at low speeds, because of its different design. The rear wheels need to be spinning before the system engages power to the front wheels, so a totally opposite driving style is necessary.

Pedal to the metal through loose stuff to get the back wheels spinning. This can be hair raising at times, especially going over crests. There’s an eerie feeling when you do reach a crest, not knowing whether to hit the brakes or keep going. The centre of gravity is rather high, and so was my anxiety.

Finally, all the Govt officials were more than impressed, and VW will apply for tenders next year. The Syncro will be available in either single or twin-cab pickup, Kombi or Caravelle. We can only hope that LNC’s wisdom will allow these models for sale in Australia, because if they do there will be a lot of Mitsubishi L300 4WDs on the used car market.

Volkswagen’s Seven-Seater Caravelle

By Paul Gover

March 1987

When you have driven all the Japanese people-movers you still have to come back to the benchmark, the Volkswagen Kombi.

The Kombi has been around since before people-movers got the name, or became a cult, but the big German remains the one that started it all. And the one which, dynamically, still sets the pace.

Forget the bells-and-whistles approach of most Japanese family vans. When you get down to engines and suspensions, the VW is still the pacesetter, despite the best efforts of the Toyota Tarago and the latest Mitsubishi L300.

The bad news for Volkswagen fans is the huge price escalation of the past few years; these days the seven-seater Caravelle is confirmed as a $35,000-plus proposition, a tribute to the decline of the dollar against the Deutschmark, even in cheaper CL form. If you want the plush GL model I recently tested for a week, then it is going to cost you $42,856 for the privilege, without any extras beyond the optional three-speed automatic transmission.

And, when you consider that air-conditioning is more than $3,200 it isn’t hard to imagine a $50,000 Caravelle.

The Japanese are catching up fast, mind you, and there is talk of a $40,000 Tarago before the year is out, but still the Caravelle is out in front for the time being. This is a far cry from the early-mid 1970s when Kombis were competitively priced, and VW had over 60% of the Australian van market. Not any more.

Volkswagen has never been a company to make changes for change’s sake, particularly with the Transporter, but a new model Kombi has just been introduced to celebrate the changeover to unleaded petrol. It looks the same as the latest-shape ‘Wasserboxer’ Transporter range introduced several years ago. The only significant differences are in the engine bay at the back.

The familiar four-cylinder boxer engine has been enlarged to 2109cc and, with fuel injection and water-cooling, the ULP power plant develops more power than the old 1.9-litre motor.

Power is now 70kW, up from 63, and torque is 160Nm, up from 140; proof that VW’s German engineers have been hard at work to make worthwhile improvements to the motor.

Otherwise the Caravelle test vehicle was very familiar, with comfortable seating for seven – including armrests to prevent driver and passenger moving around – good luggage space, and the familiar walk-through area between the front seats. It is also the safest of the people movers, with noticeably more sheet metal and legroom ahead of the driver and front-seat passenger than any of the Japanese family vans.

What wasn’t familiar, after driving the L300, Tarago and Mazda Traveller in recent weeks, was the relative austerity of the VW; no twin sunroofs, no twin air-conditioning, no cooler box, no mega sound system, no power steering, no electric mirrors or windows.

But on the top-line GL Caravelle you do get velour seat trimming, a good sound system and central door locking. The test vehicle was also fitted with an optional three-speed automatic transmission, and you can add a sunroof, air conditioning and various paint choices.

I had expected the Caravelle to drive well – after all, the Federal Police have gone back to Kombis after unsuccessful experiments with several Japanese alternatives – but even so I was surprised at how good it was.

From the start of the test it performed extremely well, particularly for an automatic with only three ratios. I had expected a few gaps, but the newly-boosted torque made light work of any hills or loads.

And, if you need to rev the engine hard for overtaking, it responds in a way I had not experienced before with a VW boxer. So, obviously, larger capacity with fuel injection and water-cooling has made a big difference.

I was also pleasantly surprised by the fuel economy and, perhaps the biggest surprise of all, there was no sign of the old dak-dak engine note which has always been the trademark of VW’s boxer engines. It was just smooth and quiet, powerful and refined; a vehicle equally at home on a short shopping expedition or a long interstate haul, where the kilometres just roll effortlessly away.

The other really good thing about the Caravelle was its ride and handling.

VW has always had its Kombi chassis right, and the newcomer has none of the front-end pitch or instability of many of the Japanese. It can be upset in crosswinds, but it never seems a real problem.

As you would expect, the Caravelle is generally a slight understeerer, pushing ahead with the power on hard. But it is light on its feet and can be hustled along surprisingly briskly, enough to embarrass some slowcoaches on the run from Lake George to the ACT border.

It also gets superb traction, thanks to its rear-mounted engine, which helps acceleration and cornering balance. It also makes the Kombi a realistic proposition even over quite rough ground.

It soaks up bumps easily, copes easily with dirt-road surfaces, and is always easy to drive. Panic-braking is a delight in the VW, unlike some skittery rivals I have driven, and a firm stab on the brakes just pulls it up solidly and square.

The Kombi also has a very solid feel and I have no doubt the current Caravelle – just like so many generations of Kombis – would go on virtually for ever.

Its passenger accommodation is very comfortable, it is easy and relaxing to drive, and once you have put it on the road it would be quite cheap to run.

It has very few faults, and quite a few small virtues. The bad points are slightly shoddy assembly, at least compared with the Japanese; poor rearward visibility for parking; and the relatively poor access to the engine bay.

But it also has remarkably good headlights, comfy armrests even for the driver, the ability to walk through to the rear passenger area, and a step to ease access for back-seat travellers.

So, despite the price, people looking for the best in family vans should not dismiss the VW Caravelle. If you can afford it, it is certainly worth having.

The WBX 6

By Rod Young and Michael Schymitzek

June 1987

Wolfsburg had just about put the six-cylinder engine on ice. This new development would probably have gone the way of other such worthy schemes and have disappeared into the archives of engine designers, if Oettinger hadn’t taken the opportunity which was handed to them by Volkswagen. What can only be produced economically in large numbers on the assembly lines at Wolfsburg can succeed when made in small numbers at Oettinger’s facilities.

Oettinger, the famous tuning company from Friedrichsdorf, just north of Frankfurt, took only a short time to develop the water-cooled flat six from prototype to production readiness. The engine is now produced by Motogema, a subsidiary of Oettinger, in a village in the south-west of the Federal Republic. The tooling handed over by Wolfsburg is used in modern, computer-controlled machines.

Oettinger, by its own admission, fills holes in the market for products that are too small for the big producers but too big for the small ones, and sees a real chance for profitability with a new six-cylinder. It’s a strong engine straight out of the box, with real reserves.

The close resemblance to the water-cooled four-cylinder is unmistakeable. In principle, what has been done is to simply add two more cylinders to the existing engine, which of course could not proceed without designing a completely new crankcase, crankshaft and cylinder heads. Numerous parts from the four-cylinder are still used. The cylinder sleeves, connecting rods, pistons and valve gear are identical. The hydraulic cam followers are naturally included.

The new engine, which has a displacement of 3.2 litres, has the same bore and stroke as the four-cylinder. Pistons and cylinder heads were designed using the heron principle; that is, with the combustion chamber mostly in the piston. The engine is tuned to run on Euro-Super lead-free (95 octane).

The already proverbial quiet running of six-cylinder engines is particularly the case with the Oettinger six. This is in no small part due to the fact that the six crank throws are arranged symmetrically and individual crank throws are counterweighted.

The greatest advantage of multi-cylinder engines is their greater torque delivery. One of the reasons for this is that with a six-cylinder, there are three firing strokes per engine revolution (every 120°), whereas with four cylinders there are only two (every 180°).

The maximum torque of the 3.2-litre engine is 260Nm. However, the majority of the power increase is brought by the increase in displacement. The high torque with its desired flat curve can only be achieved by a combination of the number of cylinders and their total displacement. What is remarkable about the six-cylinder is that its maximum torque arrives at an engine speed of 3800rpm. The 2-1-litre flat four achieves its maximum torque at 2800rpm.

Since an automatic gearbox is appropriate for such a powerful motor, Oettinger uses the three-speed Volkswagen automatic box on the buses they equip with the WBX 6 motor, and beef them up with the complete gearset from the Audi Turbo. The Transporter four and five-speed manual gearboxes aren’t strong enough for the increased loadings. An approximately 20% longer final drive ratio is used to match the maximum engine speed to the top speed the WBX 6-equipped Transporter can reach. A disadvantage is the noticeable slippage in the torque converter during gear changes – a good manual gearbox would have been better.

During the test drive, the six-cylinder engine performed just as powerfully as we had expected. Zero to 100km/h took 13.6 seconds, and 16.8 seconds more were required to reach 140km/h. Even though far better performance figures could be achieved if a four-speed automatic or a manual gearbox had been available, these times are very impressive. You must consider that this bus with its luxurious ‘Carat’ trimmings weighs in at a hefty 1820kg.

With the additional weight of 90kg of the larger engine and with the test crew and equipment on board, the motor had a good two tonnes to propel. Nevertheless, it pushed this bus to a pretty respectable speed: we measured exactly 181 km/h.

These figures just let you guess what sort of driving experience is to be had in the Oettinger bus. The power in the back allows all-round superior performance. In every situation you have the feeling that you’re driving a sporty passenger car. Rarely have we ever got so many surprised looks and gestures of approval as with this potent vehicle. The exhaust sound leads people to think that the bus is equipped with a sports car engine, and the liveliness of the car only confirms that suspicion. We found the frequent switching on of the loud cooling fan beneath the dashboard, necessary because of the increased heat output of the larger motor, to be a nuisance. Subsequent improvements to the temperature regulation should have fixed the problem, according to Oettinger.

If the 165 horses of this heavy bus are used constantly, maximum fuel consumption is 19.6L/100km. With moderate driving habits we achieved 15.3L/100km during the test. An 85-litre fuel tank is included in the specifications of the Oettinger bus.

The driving impressions are not brought by the engine alone. The stiffer suspension, which is tuned to the higher speeds, and wider wheels and tyres also contribute. On the test bus there were 215/55VR-16 tyres on 7Jx16 rims on the front, and 225/55VR16 on 8Jx16 at the rear. The servo-assisted steering works more directly on these extremely wide tyres, which is of use at high speeds but requires getting used to for some people. Also available is a wheel and tyre combination with 7Jx15 rims and 235/55VR15 tyres.

Special praise is due to the braking system. Oettinger’s WBX 6 has disc brakes on all four wheels, and a 255mm brake servo. The brakes work smoothly but powerfully. The super-wide, 40mm-lower suspension, together with the Oettinger body kit, gives the bus a mean appearance. With such an unusually fast car the front styling is adviseable, especially since other drivers often cannot properly judge the speed of overtaking cars.

For well-heeled drivers who don’t baulk at a figure of 100,000 DM (>$80,000), the Bus from Wolfsburg has become a game without frontiers.

Not as the Maker Intended

By Hans Jürgen Tücherer

October 1987

With the wave of customising kits showing no signs of cresting in West Germany, new contestants entering the battle are forced to look a little harder for a new market segment.

Fritz Ommler and Olaf Bracht, the two men behind Projektzwo Automobile Design in Diessen, thought long and hard about the car they wanted to modify. The Wasserboxer Volkswagen Bus received their nod, as there was no complete tuning kit on the market for the vehicle.

That decision out of the way, they went out, bought a Bus and began developing and moulding. Today the company can offer the works: a kit to satisfy any customer’s ideas, be they wild or mild, can be obtained from the Projektzwo workshop in the idyllic Ammersee region. Projektzwo’s body conversions can fit on all the Volkswagen Transporter derivatives, from the Bus to the Pickup models.

The front bumper is discarded and a Projektzwo front skirt is moulded to include a new bumper. The spoiler has two intakes to duct air into the front brakes and reduces aerodynamic lift to the front suspension.

Side skirts cover the wide wheels and tyres and prevent stone chip damage. The combination of the side skirts and the low-profile tyres produces an optical illusion – the vehicle looks as if it has been stretched.

Rear skirts extend behind the back wheels and again are moulded to replace the bumpers. For the Bus there is also a neat wing that is mounted to the roof.

As well as creating the muscle-car look, these modifications have aerodynamic advantages, as was proved when the Projektzwo tested in the Volkswagen wind tunnel in Wolfsburg. The coefficient of drag figure was reduced from 0.46 on the standard version to 0.425 with the Projektzwo example.

Although this achievement is not important for the customer who wants ‘show’, the guy who wants ‘go’ from this kit will benefit. “The improved aerodynamics allows us to achieve a higher top speed, and side-wind stability is also improved”, designer Olaf Bracht explained.

For the sporty driver, Projektzwo also has engine-tuning kits from the Bavarian company Schick Turbo Tuning. With a KKK turbocharger and intercooler system, Schick boosts power from the 1.9-litre boxer by 37kW to 105kW.

To gain this improvement, Tony Schick has developed a special system to cool the air into the turbocharger. The heat exchanger works together with a water-cooler at the front to guarantee optimum intake temperatures. An additional oil cooler is also fitted.

Thus the Double Cab Pickup – which is geared for towing rather than performance – has a top speed of 160km/h and a 0-100km/h time of 11 seconds. The old ton in a VW ute is fast enough for most drivers.

Handling comes in for attention too, with Boge developing a kit that includes four shorter springs and shock absorbers which have lowered the VW by 60mm. Eight-inch Ronal wheels fitted with 225/50 VR16 Goodyear Eagles maintain contact with the road.

Even with these modifications, it takes some time to get accustomed to cornering on the limit when you sit upright over the front suspension.

Sumptuous is the only way to describe the interior of this very special Volkswagen. A sports steering wheel and specially trimmed dashboard blend perfectly with Recaro seats and a special console – all trimmed in leather, of course.

A Clarion system punches out more than enough sound, and rear seat passengers have further entertainment from video films that can be shown on the TV set included in the console. Parts of the door trims are from a Porsche 928, used because they provide extra storage capacity.

Optional extras include air conditioning, an electric sunroof and electric windows. Tan-coloured carpeting in the load area and a hand-made leather tonneau cover completed the package on the car we drove.

So far, Projektzwo has shipped out 300 kits, although not all were the high-spec version we sampled. With a price tag of DM90,000 ($A72,580), it is a very expensive Volkswagen but one which is in demand.

Trakka Syncro-nisation

By Dave Berry

August 1988

Ateco Industries, in conjunction with Trakka Leisure Vehicle Conversions, have introduced the Volkswagen Trakka Syncro to Australia, offering the ultimate concept in both off and on-road driving.

The vital difference between the Volkswagen Syncro and its original Transporter stable mates is VW’s new all-wheel drive system, designed to cope with demands made by a wide spectrum of driving situations.

The Syncro system enables the vehicle to accomplish the most formibible tasks in the worst road conditions. Developed over millions of kilometres of testing through the harshest off-road environs to the demands of high-speed cruising, the Syncro performs admirably in either circumstance.

This adaptability is all due to the Syncro’s technological design. Unlike conventional four-wheel drive vehicles, the Syncro automatically regulates the additional drive to the front wheels as necessary. Speed difference between front and rear wheels is equalised by a viscous coupling. As the traction is transferred continually to the front wheels, the occupants enjoy smooth, safe ride qualities in any conditions.

The Trakka conversion of the Syncro has created a dream leisure vehicle powered by a high-performance, fuel-injected 2.1-litre petrol engine. With an extremely comprehensive range of features, the Trakka Syncro is designed to accommodate four persons in a spacious and comfortable environment. Trakka achieves this by full utilisation of the capacious interior, with the installation of swivel front seats, ‘pop-up’ roof and ergonomically designed kitchen and living area.

Other features include a hot shower, air conditioning, front and rear protection bars, and Trakka’s Solar System – designed and developed for producing power from the sun which is stored. This allows the use of the refrigerator and other electrical appliances whilst the vehicle is stationary for long periods of time.

Apart from the more conventional use of the Trakka Syncro, it fulfils numerous other functions not normally associated with traditional leisure vehicles. As a direct result of the Syncro’s incredible on-road safety and its unprecedented ride quality, it becomes the ultimate ‘family car’ as its dimensions do not exceed those of an average station wagon. This makes around-town driving, parking and general manoeuvring an effortless task.

The Syncro also offers the ideal solution to those with a sporting hobby that dominates their spare time. Apart from the benefits already established for day-to-day use, the Syncro comes into its own as a transport for surfing, equestrian, bush walking, fishing or golfing activities. Accommodation is automatically there, coupled with the ability to get to the destination required with all the necessary equipment, be it surfboards or horse trailers.

With the stylish, colour-coordinated looks and elegant design of the Trakka Syncro, the niche in the market for a highly practical, adaptable, fun ‘home on wheels’, combining normal family transportation with the ability to convert to an off-road activity vehicle, has been filled.

The Volkswagen Trakka Syncro offers an interesting and cost-effective alternative to the average family station wagon or conventional all-wheel drive vehicle.

The Volkswagen Syncro is available with front and/or rear differential locks and power steering as options. The base model retails for $39,950 and the range of camper conversions starts from $9,240 for a standard conversion to $11,944 for a Deluxe Gold Pack version with accessories available as options.

Kombi On Road To Big Van Assault

By Nick Senior

March 1989

Volkswagen is tackling the cocky Japanese van importers head-on with an aggressive re-launch of its dynamic Transporter range of commercial vehicles with slashed prices and new models.

As well as a dealer network upgraded, the major drive is aimed at grabbing sales from Toyota, Nissan and Mitsubishi. The assault is led by the newly introduced windowless version of the Volkswagen Kombi panel van, which will sell for $19,995.

The popular Kombi van with windows, which is ideally suited for camper conver¬sions, has been reduced from nearly $30.000 to $22,450. A Deluxe version has been introduced, and this costs $25,400. Trakka camper conversions for the Kombi will be available from an additional $10,007.

The Caravelle GL, which formerly sold for $39.990, drops to $32.600. The executive version called the Carat has been introduced too, but prices aren't available yet.

There will be three versions of the all-wheel drive Syncro. They are the Kombi at $32,450, the Kombi deluxe at $35,970 and the Caravelle, which will sell for $46,990.

A fuel injected 2.1-litre 4-cylinder engine that produces 70kW powers all versions of the Transporter.

Volkswagen is also evaluating a new recreational type vehicle for Australia. It's called the TriStar and it combines 4-wheel drive capability, five-seat passenger capacity with the load space of a utility. All going well, the Tristar will make its debut in Australia towards the end of this year.

Other Volkswagens which will make their debut this year include the double-cab Pick-up models and two versions of the Golf GTI hot hatchback, most likely the 8-valve and 16-valve variants.

Volkswagen has been a dormant force on the Australian market for more than a decade but these are major signs of an overdue recovery.

Kombi Makes a Comeback

By Wayne Webster

March 1989

The VW Kombi, the conveyor of 1960s hippiedom, surfies and the forerunner of people movers, is about to make a comeback to the Australia market.

Volkswagen is about to launch itself back on to the commercial market with the new generation Kombi. Sydney-based importer Ateco Industries Ltd has negotiated with the German carmaker to import and retail the Kombi range at prices ranging from just under $19,000 to a top of $46,990.

These prices, coupled with the marque's reputation for ruggedness and long-lasting reliability will make the Kombi competitive once more with Japanese brands.

Ateco also has revealed that it will follow up the Kombi beachhead by launching two models of VW's Golf GTI hatchback, currently Europe's hot small car, later in the year.

Our current high exchange rate and the state of our new car market certainly provide the right incentives for VW to test Australian market reaction now to its products. The chance here to buy a VW again, at the right price while it lasts, will no doubt prove attractive to the market.

According to Ateco, a range of Kombis will be offered, from the basic $19,995 panel van to the top-of-the-range viscous-coupled 4WD Syncro Caravelle.

Camper conversions options will be available, costing $10,007 for the basic layout and $12,774 for the Gold Pak kit.

Common to the range is a 2.1-litre fuel injected engine, producing 70 kilowatts.

The 1989 Kombis, unlike the ugly-blue beasts that traveled our roads in the 50s and 60s, come in a choice of colors, have a much different grille, square an round headlights (depending on models) and, like most new cars today, feature bigger areas of glass.

All vans in the range feature the unique VW facility that allows the driver to get to the rear load-space without leaving the vehicle.

According to Ateco two double-cab pick-up models — in both two and four-wheel-drive — also are to be released later this year. The 4WD version of the double-cab pickup will be equipped with extra accessories and sold as a lifestyle model called the TriStar.

The people mover of the range is the Caravelle, which in its basic two-wheel drive form, costs $31,145 - a still hard to afford price for most larger families but with a few extra features that help to compensate for this price sticker.

The seven-seater, velour-trimmed interior mini-bus, features power steering, central locking and is carpeted throughout. A tachometer and digital clock are part of the standard instrumentation. And the quad, square-shaped headlamps, also feature in-built driving lights.

Trakka Vans Attract the Fans

By Dave Long

August 1990

In Dee Why recently, not far from my home, I parked my Ghia opposite a really smooth-looking current series VW Transporter.

Now modern Volkswagens, however practical, are not my bag (mainly because I can’t afford them), although I can recognise a good thing. The VW bus, in a colour resembling pewter metallic, grabbed my attention more for its ‘CARAT’ registration plate than for its immaculate showroom presentation.

This particular Kombi is Trakka Van Conversions’ example (as the number plate announces) of the VW Carat, normally available only in Europe. The Trakka Carat, whilst not the genuine article, is very nice and may be, in some aspects, in its way more opulent than the original.

To track down its operator, I began by asking in the household appliances spares shop outside which it was parked; no luck – next the second-hand shop a few doors down. There, expecting the Carat to be the type of spotless vehicle a boutique owner might choose (and bankroll) I barged in, asking nosy questions. The shop assistant couldn’t help with the identity of the Carat owner, but the young lady customer with the two children owned up – it was hers.

Prior to this I had planned on leaving a note under the Carat’s wiper, but as it worked out this wasn’t required and Sally Berry, wife of Trakka proprietor Dave Berry, accepted my bona fides after a brief explanation. And then expressed interest in joining our club!

So I arranged for a call on the Trakka organisation at Chatswood, Sydney, for the purpose of photographs and to fill in some gaps in the information first-hand.

I was shown around by the sales manager, Noel Ryan, a man of similar vintage to Dave Berry, the Boss – that is, middle-forties. He has been connected with the motor trade since leaving school, beginning his career in the early ‘70s at Scuderia Veloce, Lindfield, in spare parts, so he picked up a passing knowledge of Porsches, too, in particular the early ones (the 356 was virtually a current model back in 1973).

Trakka Pty Ltd is located in Short Street, just a zig-zag up from Eastern Valley Way, in neat and efficient-looking premises housing both showroom and factory. Parked outside on the day I called was a fair selection of recent and not-so-recent VW commercial vehicles, including a new twin-cab pickup, window-vans and a couple of ‘70s Type 2 camper vans which may have either been there for fitouts or resale, as Trakka also handles used examples.

Trakka began in the mid ‘70s, converting VW Kombis into camper vans. They became the officially VW-authorised Australian camper van converter in 1987, when LNC Industries sold the Australian VW franchise to Ateco. LNC had owned the previous conversion company, Sopru, which was sold to Trakka at the same time. Today, all but 10 percent of Trakka’s business involves VWs; that which isn’t covers Toyota. Then, of course, no one is perfect.

Their marketing arrangement is organised through the network of VW dealerships Australia-wide, and as with most commercial operations is based on mutual profit. The dealer carries a range of literature showing the scope of conversions available, and the wide range of options. It is assumed the customer will be aware of Trakka products from visits to motor shows, or the awareness of the availability overseas of something comparable.

Trakka appoints a stockist in each state, who has a fully appointed demonstrator vehicle available. It may just as well be, however, that a customer comes to the dealer with nothing more than a concept or a requirement to fill. Trakka would not wish to give the impression that they are in the ‘custom vehicle’ field, while I got the impression they would cooperate in any reasonable specification according to price. Noel Ryan believes though, that the scope of available options and routine modifications is such that most tastes are catered for.

And he shamelessly slips in the plug, “where our business is concerned, nothing is impossible with VW.”

The range of VW-based conversions possible totals seven, price dictated both by the model chosen as the basis, and the embellishments ordered.

The most basic of the range starts with a window van converted to a 5-seater multi-purpose station wagon, with folding back seat. Starting price is $28,500, but if you want the conversion done on a Syncro 4WD van it can be as much as $42,000.

Next is the ‘Multi-Van Gold Pack’, which is the basic conversion with a pop-up roof and some revised trim, sleeping four adults for $30,000 to $40,000. The simplest model is seen as a family vehicle, while the second is intended for a combination of work vehicle and weekend camper.

The ‘Bronco Standard’ comes next, in the form of a basic budget camper with pop-up roof, cupboards, stove, bed and fridge, priced from $36,000 to $50,000.

Then you come to the ‘Bronco Gold Pack’, which adds luxury items like orthopaedic front seats (developed by Trakka in Australia), with arm rests and swivel bases, radio cassette and alloy crash bars front and back, priced between $42,000 and $56,000 (always depending on the level of VW model on which it is based).

At level 5 we find the Trakka ‘Time’, which is debatably the most costly vehicle in the range (even though it is not the top model). Somewhere in the $55,000 to $70,000 bracket, in addition to all the fundamental appointments, you get touches such as leather upholstery, hot water and shower, air conditioning, 15” wheels with premium tyres, and a skirt and spoiler kit.

Number 6 is known as the Carat Seven (7-seater), which deletes the two orthopaedic seats and the fridge, and substitutes a full-width 3-seat bed seat. This one costs from $48,000 to $60,000.

Finally there is the Carat – the model on which this tale opened, and it costs $50,000 to $61,000. The specification goes something like this: orthopaedic seats, two of them swivelling 360-degrees, all covered in English leather; 40-litre eutectic fridge, air conditioning, full velour headlining, full carpet, reading lights for each seating position, and a pull-out conference table. The notion isn’t lost on Trakka, nor any of their corporate customers, that the Carat makes for a brilliant and sophisticated mobile office.

In case they appear to have missed anything, a couple of the many further options are – various annexes and solar battery charging.

Just a spot of detail on the way a standard VW Transporter arrives at Trakka’s premises to be transformed according to buyer’s choice. The subject Transporter, typically a Window Van, arrives at the factory still with the protective shipping wax still covering the paintwork. Luckily it removes simply. The van is delivered standard, zero km, with one important distinction – it has been assembled with 50mm of reduced suspension height from the factory, and has the latest VW factory alloy wheels.

Usually the two front seats are upgraded, the door trims and other trim board substituted in material to match the newly lined roof, using a type of velour fabric. Starting with version 1, in goes the folding back seat, and that’s about it. The others get their further amenities according to price – some including the Indel ‘Made In Italy’ high efficiency fridge, for which Trakka has the Australian agency. The company has the distinction of having developed and supplied a compact compressor to the US Space Shuttle program that operates at full efficiency in any position.

This insight into the operation and functioning of Trakka Van Conversions Pty Ltd was not intended as a promotion for the company, and I have resisted the tendency to get carried away with enthusiasm!

Volkswagen's New T4 Bus

By Rod Young

August 1990

It's finally happened. Volkswagen presented to the public at the end of August its new Transporter, named the T4. The Type 2 in its previous three generations has served its time, at least in the two-wheel-drive versions. Only the Syncro will survive in the old shape for the time being. The amount of appreciation showed by customers for the old rear-engined bus is shown by the fact that the entire production for 1990 has already been accounted for - completely sold out.

Perhaps people should have waited to see what the new Transporter has to offer, because it really is a great deal. Firstly, an entirely new concept: all T4 variants have only front-wheel drive and a transversely mounted engine, which is hidden underneath a short engine lid. This is exactly what the market demanded. When compared to the old Transporter, this layout creates a vast amount of room at the rear of the vehicle, for example for carrying passengers or goods. An excellent ride and ideal space utilisation along with compact exterior dimensions can therefore be expected. The advantages of the old Transporter – the ability to be driven like a car, but with much more room available – are found to an even greater degree in the new Bus.

The T4 forms the basis for a large number of different body variations for the most different of applications. From the Caravelle to the Pick-Up, Double-Cabin and Delivery Van to the Kombi, all the variations, which made the old Transporter such a multi-purpose vehicle, will be available. In addition there will be a vehicle consisting of the bare chassis and cab, which will serve as the platform for special body constructions, such as camper vans and special utility vehicles.

There will be an option of two different wheelbase versions, 2.92 and 3.32 metres. With the Caravelle and the Kombi, this will mean that instead of the usual nine seats, up to twelve positions will now be possible. In future there will be three weight classes of commercials, with ratings of 800, 1000 and 1200 kilograms. Until now the upper limit was 995 kg. For trouble-free loading, there will be a large rear hatch or two swinging doors. The sliding side door is still there, and double sliding doors can be ordered. In the Caravelle the seats can easily be removed, or else the rear seat cushion can simply be folded down to make more loading room.

Three petrol engines and two diesels make up the choice of power plants. All were chosen on the basis of high torque and durability. At the entry level is a 1.8-litre four-cylinder in-line engine with 49 kW / 140 Nm and a carburettor. This engine was conceived mainly for countries that don't have a sufficient supply of lead-free petrol. Then there is a 2-litre five-cylinder with 81 kW / 190 Nm, fuel injection, catalytic converter and oxygen sensor. The petrol motors reach their peak power at 4300 and 4500 rpm respectively.

A 1.9-litre four-cylinder diesel with 45 kW / 127 Nm, and a 2.4-litre five-cylinder with 57 kW / 164 Nm are both available. Both achieve their maximum power at 3700 rpm.

All models have as standard a five-speed gearbox; a four-speed auto is an optional extra.

Together with the improved Cd of 0.37, quite substantial performance can be achieved. For example, VW indicates a figure of 11.4 seconds for acceleration from zero to 80 km/h for the 2.5-litre five-cylinder-equipped Caravelle. The top speed of this same vehicle is given as 161 km/h.

Suspension and brakes are also new, as front-wheel drive presents particular problems concerning varying vehicle behaviour when loaded and unloaded. At the front, independent suspension with double wishbones and two longitudinal torsion bars provide good tyre-to-road contact. With this design more room is also provided in the footwell of the passenger compartment. At the rear are semi-trailing arms with coil springs.

The suspension design and component tuning are reported as providing a balanced driving feel at all load conditions. The braking equipment consists of a hydraulic twin-circuit brake system with diagonal split - discs at the front and self-adjusting drums at the rear as well as power assistance and a pressure regulator that is specially controlled by a balance lever. The new pressure regulator is supposed to guarantee that the high degree of stability achieved by the suspension is maintained while braking through curves.

It is welcome that the increase in interior room is not accompanied by larger exterior dimensions. The short version is 4.66 metres in length (the long version is 5.055 metres), ie. 8 centimetres more than the existing Type 2. The width of 1.84 metres remains unchanged, as does the height at 1.94 metres. The dimensions of the interior loading area are given as 2405 x 1620 x 1415 mm.

It is obvious also that the new Bus will be heavier than its predecessor. For example, the T4 with 2.4-litre diesel weighs about 1640 kg and reaches a legally allowable gross weight of 2540 kg. Maximum trailer weight, depending on total vehicle weight, is up to 2000 kg.

We're looking forward to a first test drive, even if it's not yet clear when the first T4s will be in dealers' hands. Then we'll see if the new flash van from Wolfsburg can impress enthusiasts for the old Type 2. This will also be a question of price, which has not been announced at this stage.

South African Muscle Bus

By Geoff Dalglish

August 1991

Volkswagen of South Africa has staged a spectacular coup d'etat with the launch in February this year of the 2.5 litre five-cylinder Kombi.

You don't have to be a rocket scientist to appreciate that the new Volksie has further distanced itself from the Japanese opposition. To use the jargon of the '90s, it's South Africa's definitive luxury MPV – Multi-Purpose Vehicle.

Arriving on the scene just months after Wolfsburg has switched to an aerodynamic new front-engined design for the T4, the uniquely South African development is a triumph for local ingenuity. Not only is it more powerful than the 2.1 litre version it replaces, but quieter, more comfy, and as stylish as a brick-shaped minibus dating back to the ‘Seventies can be.

Fitment of the locally engineered Audi-derived 2.5-litre engine boosts power 22% from 82 kW at 4800 rpm for the familiar 2.1 litre ‘wasserboxer’ engine to a muscular 100 kW at 5000 rpm. The torque gain is no less impressive, although admittedly at higher revs, soaring from 174 Nm at 2800 rpm to 200 Nm at 3500 rpm. According to VW's claims, it will now accelerate to 80 km/h in 9.2 seconds, while clocking a genuine 164 km/h at sea level.

Changes also go way beyond the engine. Most obvious is the new frontal treatment with new front grilles and bumpers, and larger windows for rear seat passengers.

A welcome innovation is a jump seat that folds down into a table or armrest, and allows walk-through access to the rear. Fitting the bigger engine has necessitated raising the floor of the rear luggage area slightly, but although some luggage area is lost, there is a bonus of two additional storage compartments and a facility to told the seats flat to form a bed.

A five-speed gearbox is standard, although first is rarely necessary; it's better to shift from second to fifth in the normal H-pattern instead. Shifts are smooth and precise, and the van has effortless power with quiet running thanks also to extra sound deadening.

On the open road it cruises at 120 km/h with only a light touch on the accelerator, and proved able to flatten most hills in fifth at sea level.

Although a minibus can never be quite as easy to manoeuvre as a car, the Caravelle comes close, pampering its occupants with every imaginable luxury, including that superb overhead console air-conditioner, plush seating with flip-down armrests, electric windows and mirrors, central locking, tinted glass, height adjustable front seatbelts, full instrumentation, a four speaker sound system, and alloy wheels shod with 205/70 tyres.

As you'd expect, the price is in keeping with its ‘German Luxury Car’ status, with the manual Caravelle costing R79,420 and the three speed auto R81,480 (That’s $36,100 and $37,040 in Aussie dollars). About the only option is metallic paint at R400 ($A182); an alarm and immobiliser is standard.

By contrast, the Microbus foregoes some of the luxuries to arrive with a price tag of R61,130, or R63,200 for the auto. Again, I'll convert that for you Aussies; that's $A27,787 and $28,728 respectively.

VW Is Back With A Vengeance

Daily Telegraph (1982)

February 1992

Volkswagen came back into Australia last week with its first new commercial vehicle release in 15 years. The new arrival is the Transporter range of light commercials - a Microbus and a Kombi.

The Transporter is impressive in all departments, including price, which ranges from $10,995 for the manual Kombi to $14,996 for the deluxe automatic Microbus. Critics have been quick to point out that the top of the line in Japanese eight-seater buses sells for under $10,000 and has more comfort in many areas.

This may be so, but the Transporter range is a well engineered series that will have no trouble whatsoever in disposing of 1,000 units a year in Australia. This is the figure that has been mentioned by Mr Dick Higgins, general manager of Volkswagen Australia. Last week he said the company could no longer expect to dominate this segment of the commercial market.

Volkswagen Australia will import 1000 units a year, split equally between Kombi and Microbus.

The Kombi freaks will come out of everywhere, and there are individuals and businesses that will certainly spend the money to buy what they consider to be the best in terms of reliability and quality in the light bus field.

Of course there are faults.

Like all light buses and vans, the Transporter tends to catch the cross winds, but people with ex¬perience driving these types of vehicles know how to handle that. Dust is inclined to gather thickly on the back window. Maybe a roof-mounted foil would help here. There seems to be a little trouble with the near side seat belt in the middle row of seats when using the sliding door. The vinyl seats get hot and sweaty without air conditioning, and one expects cloth seats in a vehicle costing almost $15,000.

Another fault with the front seats is that there is a lack of under-thigh support, and you feel you are slipping forward, particularly when driving. Side support seems sufficient and would definitely be better on cloth seats.

No doubt there are other faults, but a first look at the Transporter shows a top class multi-purpose vehicle.

It has very good visibility, the handling is excellent, the ride superb, it is quiet and comfortable for both driver and passengers and it gives a wonderfully safe feeling. Moving downhill at above average speed, the Transporter negotiates even fairly sharp bends with ease and without causing any white knuck¬les among the passengers.

Last week, Mr Higgins said that the initial shipment of 199 was already spoken for. It is easy to see why.

The Kombi and the Microbus are back and they look like staying for a while.

RHD T4 Caravelle

By Phill Lander

March 1992

A whole year after VW first unveiled this front-engined, front-wheel-drive people carrier, the Caravelle has finally been made available in right hand drive. The delay might seem surprising; you’d have thought that the company would be keen to eat into the expanding people-carrier market in the UK as soon as possible. But there’s a good reason for the delay: 30,000 European butchers, bakers and pretzel makers are waiting for their new Transporter vans, on which the Caravelle is based. Volkswagen has decided to concentrate on filling these orders before building large numbers of Caravelles. The company’s commercial vehicle factory in Hanover is producing 700 Transporters per day, 150 more than it achieved with the old rear-engined, rear-wheel-drive Transporter.

With British prices ranging from $A38,500 to $A47,300, the Caravelle is pitched directly at Renault’s Espace and Toyota’s Previa (Tarago). But unlike these two, and most other purpose-built people carriers, the van-derived Caravelle has ample room not just for passengers, but for their luggage, too. There’s enough space behind the rear seats for at least six suitcases, and more if you’re willing to sacrifice some rearwards vision. Two versions of the Caravelle are available: the GL, which comes with seven seats and has the higher spec trim; and the CL, which comes with eight seats as standard (a ninth is optional) and is less well equipped.

The middle row of seats in both models can be removed at the flick of a couple of levers, which creates even more luggage room; and a few minutes with a spanner will have the back seats out too, thus turning the Caravelle into a carpeted Transporter.

A large sliding door makes loading the VW child’s play. As well as being easily removed, the middle seats fold down to make a table. The back of the GL’s seat is covered in a hard plastic moulding, with indents to hold drinks. Both the driver’s and front passenger’s seat can be swivelled around to face backwards.

There's no doubt that you're driving a Transporter when in the Caravelle. The steering wheel is more upright than a car’s, and you sit with your knees bent at right angles. It’s comfortable, though, and in the GL you even have an armrest for your right elbow.

Both the GL and CL versions have well made and sensibly laid out facias, which borrow switches, knobs and stalks from VW saloons. The GL has more doolackies than the CL: central locking, rev counter, electric door mirrors, contoured seats, power steering (which the diesel CL has as well), and metallic paint.

Three transverse engines are available for RHD Caravelles: two petrol motors, a 63 kW 2.0-litre four cylinder and an 82 kW 2.5-litre five cylinder, plus a 58 kW 2.4-litre diesel. All Caravelles have five-speed gearboxes as standard.

The Caravelle has independent front and rear suspension - semi-trailing arms at the back; double wishbones and torsion bars (which cleverly keeps the footwells clear of intruding coil springs) at the front. This car-like suspension set-up makes the VW a great handling van like its predecessor, but unfortunately it’s not up to Espace standards. The VW, after all, is 230 mm longer than the Renault, and on the road it feels it. The upshot of the extra size is fine ride comfort, better than the Espace or Toyota. The Caravelle smothers big bumps, but has a tendency to pitch. Push it too hard and it starts to understeer, and because you sit high up it feels more out of shape than it really is. Drive it like a Transporter, however, and it wont let you down. And it certainly doesn't gyrate the way an old Ford Transit would if pushed too hard.

I drove the GL version, fitted with the 2.4-litre diesel. Volkswagen quotes a top speed of 140 km/h, a figure easy to achieve, and one which is quite adequate for a vehicle capable of carrying so many people. Strong low-down torque makes the diesel VW relaxing to drive in town, endowing it with decent acceleration and good lugging ability - something missing from buzzy, high-rpm Toyota engines. VW also quoted an average fuel consumption of 9.4 L/100 km while we burned slightly more - 10.0 L/100 km.

As a pure alternative to the Renault Espace, the Caravelle is not quite suitable. It’s too much of a van, not quite enough of a car; too big on bulk and a little short on luxury. But for football teams, antique shop owners and especially old Kombi owners, it makes a lot of sense.

The New Volkswagen T4 Transporter

By Phill Lander

November 1992

Released at the Sydney International Motor Show, the new Transporter/Caravelle range is the safest and most environment-friendly ever.

Prices for the new commercials are still competitive with the Japanese vans at $24,750 for the panel van and $29,900 for the window van, and with Volkswagen's superior quality and reliability should sell well. The Caravelle should go on sale in a few months time and will hopefully be priced to compete with the Toyota Tarago. With TKM advertising the Caravelle on its safety features it must be a better alternative as a family bus.

Through three generations covering 40 years of production, the Transporter became the most popular commercial vehicle of all time. Nearly seven million sales worldwide are a testament to its success and versatility.

Now comes the new Transporter, a brand new vehicle developed at enormous cost to take van owners into the next century.

Much thought and care has gone into every aspect of its design. From the front engine with front wheel drive, to the low flat load floor and the large tailgate. From the moulded dashboard and door panels, to the independent suspension front and rear. From the aerodynamic shape, to the extensive anti-corrosion treatment.

The front engine, front-wheel drive layout of the new Transporter has allowed Volkswagen's designers to create a van for all trades and businesses.

At the near side a sliding door is supplied as standard so that you can take full advantage of the 5.4 cubic metres of load space.

All this load space hasn't been supplied at the expense of overall dimensions. The new Transporter is truly large on the inside and compact on the outside. At less than 2 metres high, with the standard roof, it should fit into a standard garage or multi-story car park with ease.

Whether in congested city streets or on the open road, the Transporter is easy to drive with features like independent suspension to give car like ride and handling.

From the moment you open the door the new Transporter looks inviting. The cab doors now open behind the front wheels and the wide, low entrance step makes the access very easy.

Creating the best possible environment for the driver was the priority for the Volkswagen design team. Once you’re behind the wheel the fully moulded dashboard and door panels, and comfortable seating help you to forget it's a van at all.

As you would expect from Volkswagen, there is a heavy emphasis on safety. Like its predecessor, the new Transporter has a deformation zone built into the front end of the vehicle to aid passenger protection in the event of a collision.

The new Transporter is unique amongst commercial vehicles in having independent suspension front and rear. The compact front suspension uses double wishbones and torsion springs together with short shock absorbers, so that none of the components project into the footwell area.

At the rear, diagonal trailing arms and coil springs are used. Again a compact arrangement has been achieved by mounting the shock absorbers below the load floor. This design gives the large through-loading width of 1220mm between wheel arches of van models.

Extensive anti-corrosion treatments are applied during manufacture, including dip-degreasing, zinc phosphating and cataphoretic priming. In addition cavities are flooded with hot wax as a further protection against rust.

T4 Caravelle Road Test

By Philip Lord

November 1993

To have a tribe of kids can be a mixed blessing. You can easily cope with carting your own in the Beetle, Golf or Passat, but what if they want to bring friends? Or what if you have more than three kids?

This is where passenger vans come into the picture. Vans like the Tarago have become very popular for their ability to handle the rigours of being the large family's workhorse.

The VW Caravelle (and before that, the VW Microbus) passenger van has been available in Australia for many years, but has long been at the mercy of the Japanese manufacturers with their ability to undercut on price. Now that prices of Japanese vans are climbing higher, the Volkswagen Caravelle has become price competitive.

The Caravelle has the 2.5 litre five-cylinder engine and 5-speed manual as standard. Major options for the Caravelle include auto transmission, air-conditioning, alloy wheels, bull-bar and tow bar.

Heading for Palm Beach one-up, it was hard to gauge what the performance and ride would be like fully loaded. However, as it was, the van’s performance was quite acceptable (especially off the mark), and while the suspension did feel a little choppy, this is not unusual for a van design such as the Caravelle.

The Audi-sourced five produces a pleasant, unobtrusive growl when provoked, and is smooth through the rev range. No torque steer was evident despite the front-wheel drive design.

The test vehicle was fitted with a 4-speed overdrive automatic transmission. It was smooth in operation and had good kick-down response. I noticed that in traffic or on the winding Barrenjoey Road, it was better to lock-out 4th gear so as to avoid riding on the brakes. While the gear selector is well positioned, it would benefit from a gate such as Audi's, to avoid slipping past the intended gear, as is easy to do with the long angled lever.

The seats seemed softer than those fitted to late-model Passats (they look virtually identical) and are quite supportive. Access to the front seats requires a definite step up, and can be awkward to negotiate, especially as there is no grab handle. Once seated though, there is ample view foward, and one cannot escape the feeling of riding over the front wheels. The seating position is high and bus-like.

The Caravelle's advantage over other passenger vans is its superior size. This is a double-edged sword, as its roomier cabin space naturally means a larger exterior, with all the ensuing perceptions of unwieldiness, heavier fuel consumption and so on.

At $42,990 (manual) or $45,690 (automatic), the Caravelle is not cheap. However do some shopping around and you'll see that nothing else in this category of vehicle is either! With Volkswagen's reputation for over-engineering their cars, one might expect that the Caravelle will last the spills and scrapes of family car life much longer.

Syncronicity - Bus mit Allradantrieb

By Simon Matthews

February 1995

The combination of the Volkswagen Transporter and permanent Syncro all-wheel-drive transmission providing a go-anywhere people and/or goods mover has been one of the best ideas to come out of the VW Group so far.

I lucked onto my 1988 Syncro Transporter after spotting an advertisement in the Trading Post. The third-generation Transporter shape had always appealed to me and I had looked at buying several two-wheel drive versions before. The Syncro was reasonably priced, and following an inspection decided that it was too good to resist. My Audi 5+5 was sold off and I became a boxer owner once again.

Despite being beautiful, clean and in surprisingly good condition for a commercial vehicle, there were a few items to attend to following its arrival home. The original shock absorbers were well past their use-by date and desperately needed replacing. These, combined with almost-bald original 205x14 Michelin X street-type radials allowed the bus to spin all four tyres in the rain one afternoon coming through a fast comer on the way home from work. Some better rubber was required if the bus was going to stay shiny-side up.

The shock absorber problem was tackled first. Original equipment units from VW were priced way out of my league, and so an alternative had to be found. It seemed that aftermarket shocks for a Series 3 Syncro Transporter were going to be difficult to find. Both Bilstein and Koni did not list a part number for such items, but Active Suspensions in Hornsby Heights was one company that could make a set of Koni adjustable Special Ds to fit the bus for considerably less than the original replacements. Following the excellent results of fitting Konis to my Audi, this was definitely the way to go.

After adjusting the shocks to half firm it has not been deemed necessary to re-adjust the units since. Not having driven a Syncro with decent original shocks it is hard to compare how the Koni-equipped bus rides. When empty it is definitely on the firm side but improves greatly with a load on board (i.e. other than a car-full of drunken yobbos at Valla ‘93).

The wheels and tyres have probably caused the most headaches of any mods to date. After pricing off-road tyres to suit the original 6x14" steel rims it was decided to up the ante to 7x15" rims for improved looks and a wider choice of tyres. Several problems then arose. As with the shocks, the Australian aftermarket wheel industry was not brimming with items for late Transporters. Most reasonable-looking alloy wheels that we checked out were (a) not available in 5x112mm PCD and/or to suit M14 wheel studs, (b) the wrong offset, or (c) had flat centres that would not clear the rear stub axle nuts etc. etc.

Eventually a set of 5 spoke Performance Austar alloys were chosen for their ease of fitment and good looks. Their open design allows them to be easily cleaned, a job that occurs quite often! Several new alloy wheels to suit the Transporter have been released since I went through all this, so setting a Syncro up with alloy wheels nowadays is not as hard as it used to be.

The choice of tyres was again a matter of compromise. Realistically, the Syncro would mostly be used on the street and see little (if any) real off road use, so an aggressive mud tyre would destroy the superb ride afforded by the Konis, as well as handling suspiciously in the wet. Transporter Syncros, although 50mm higher than the 2WD variant, are still limited in the size of tyre that will fit under the guards. A set of 225/70R15 Dunlop Grandtreks fitted the bill perfectly, being a predominantly road tyre but with a reasonable mud/snow pattern for occasional excursions into the bush. Clearance from the left rear tyre sidewall to the inside edge of the open sliding door is about the width of my smallest finger, almost too close for comfort!

With the bus now running and driving okay it was time to turn the attention to the interior. Although fitted with a Camperize rear seat that folds down to form a double bed, the bus came with the basic austere trim it left Graz with, including bare painted steel everywhere, including the rear floor. Having the side and rear trim panels reupholstered in 'frontrunner’ cloth provided a more homey atmosphere, and a carpeted plywood floor made the interior much more presentable. So far I have not extended the roof lining from front to back, this job being included in the list of things to do One Day. The original gauge cluster was replaced by a ‘Euro’ version including a tripmeter speedo, tachometer and 24 hour digital clock. The original fuel and temperature gauges were modified to fit in the tacho face.

The 70 kW 2.1-litre 'waterboxer’ catalyst motor has been kept absolutely standard for the sake of reliability and driveability. A Finer Filter polyurethane air filter and stainless steel muffler are the only additions so far. Combined with the ‘4+G’ gearbox the big bus will move along quite respectably and will easily see off a 4-cylinder T4 in a traffic light drag. In fact, the first time I used the rev limiter was to run an enthusiastic Tarago driver and left him languishing behind. Such driving does not pay dividends at the petrol station however, because motoring at any decent speed will see the fuel gauge drop quite alarmingly. Round-town driving normally sees the bus return about 12 litres per 100 km, and the tank holds 70 litres.

A Camperize alloy bull bar and Cibie Super Oscar driving lights are the only external mods. These lights, combined with 90/130W headlight bulbs produce a brilliant display of light and ensure that I can always see where I'm going. Many thanks to Phill Lander for his factory-type wiring job on the lights and relays.

The Syncro has not done much off road work since its purchase, being used mainly as a very practical daily driver. The roadholding is now very good and the visibility in traffic is superb. Looking down on lifted 4x4 Hiluxes and Landcruisers is especially satisfying. I did, however, get a chance to use the Syncro in anger in the bush last year when a friend of mine, Mark (a Landcruiser owner) organised half a dozen or so of us from work with 4WDs to try a track known as ‘Long Angle Gulley’ at the base of the Blue Mountains, starting at Blaxland and finishing at Winmalee. The track is about 10km long and is rated as 'very easy' 4WD, being used for club driver training and the like. We amateur off-roaders should have no problem making it through, or so we thought...

Heavy rain the week before had created quite a lot of mud in places and had washed deep ruts into sections of the track. Mark acted as tour guide and showed us the right way to read the track surface, where to put the wheels for maximum grip and so on. It was stressed that slowly was the way to approach most off road situations, with the very real possibility of car damage as a consequence of doing something stupid.

Immediately the choice of tyres on all vehicles became important as to how well they performed. Mark's mega-Landcruiser with 12.5 x 33 inch tall BFGoodrich Mud Terrain T/As had no problems with the track, but my (street type) Grandtreks easily filled with mud and did not self-clean as easily. We soon learned how much throttle to apply without spinning the wheels uselessly. By travelling a section of the track one car at a time, road building where necessary and having lots of help available in case of trouble, we moved cautiously forward. The 6.03:1 Gelandegang (off road gear) in the Syncro would allow it to climb hills that I would have found difficult to walk up. The absence of power steering made hard work of the constant wheel corrections necessary to keep the bus driving forward, but being seated over the front wheels made it very easy to place the wheels exactly where they were needed.

Comparing the performance of the Syncro with the other 4WDs in our party, several things became apparent. The first was the lack of wheel travel. At any crossing of a dip or bump at a skewiff angle, the Syncro would lift wheels off the ground. One especially deep ditch turned it back into a 2WD as it picked two diagonally opposite wheels up. Some judicious lifting on the rear tow bar by three other party members to put both front wheels back on the ground soon had us on our way again. A locker diff for the rear axle would provide drive even if the car has wheels in the air. For serious bush driving, they are a must.

The only other problem was approach and departure angles. Being a forward control van, the long nose meant that rock steps and sharp rises had to be treated with a great deal of caution. Some minor scurfs on the bottom of the bull bar were the only marks I put on the bus all day. Fortunately, there are side tracks around some of the more ‘challenging’ sections and by sticking to these the impact on the cars was minimal.

The only major problem we had was Mark's Landcruiser breaking a front CV joint after jamming the wheel between two rocks while climbing a very steep hill. We spent our lunch break cleaning the broken parts out of the axle tube and the Cruiser finished the rest of the track in 2WD only with no sweat.

All in all, I was very impressed with the performance of the Transporter Syncro. By the end of the day my confidence in the car's ability had increased 1000%. It is surprisingly capable and, given more suitable tyres and a few other mods, would be able to go just about anywhere. I don't think I would like to take it bush too often though, because cleaning it is one hell of a job!

Syncro Kombis at the Range Rover Test Area

By Jeff McKenzie

May 1997

On a gorgeous autumn morning, two Syncro T3 Camper Kombis attacked the Range Rover Test Area, with good results. Derek Drew and I took our '90s and our families out for a little mud, muck and Syncro Madness.

The spot is some old farmland that the Range Rover people have set up for demonstrating their vehicles. It is traversed by a series of very rutted ‘two tracks’ up and down moderate hills, into gullies, in both bush and open land. Many of the ‘roads’ in the open areas remind my wife of central Africa, where she worked for several years.

Its nice to go to a place like this with a buddy vehicle to keep you out of trouble (or to share the trouble you get into). We did find trouble, too. Recent rains had left standing water at all the low points, and recent Range Rovers had made some gnarly ruts in the clay soil. Their tyres are much bigger than the Syncros’!

No gates for the Range Rover Test Area, just bulldozed up a couple of large berms up at the end of the paved entry road to keep out the riff-raff. Up and over we went, and in about one minute we were pretty nicely stuck.

Now, Derek's philosophy is that to get anywhere interesting, you have to be willing to get stuck. We had just gotten past one mud pit when the lead vehicle got caught just at the beginning of a second. Those Rover ruts are deep! We hooked up a tow strap, and with the diff locks on, backed up like a little train, retreating to the more solid stuff between the two quagmires.

We de-aired the BF Goodrich Radial All-Terrain size 27LT8.5-14 tires (both vehicles run these - they are the ones you want, folks) to about 18 psi, reconnoitred the mess on foot, repositioned to attack from the side, and proceeded through.

Soon we were at the ‘Pyramid’, a three-metre mound of dirt set on a little plateau. Three sides have been packed at somewhere between a 25 and 45 degree angle, and there is just enough room on top to stop your vehicle for ‘hero photos’. For added effect, there is standing water (actually, standing mud) around the base. The key to climbing this little hill is the friend of all VW Kombi drivers, momentum. You get a running start, and head for the hill, prepared to launch. First you hit the mud, which sprays up all over the side windows giving you a tunnel effect, and then you realise that there is nothing in your forward range of vision but this hill, and it is about two metres ahead of your windscreen. Of course, your windscreen is forward of the wheels, and a millisecond later you see nothing but blue sky as you start the ascent. In another millisecond, the hill levels out abruptly (somewhere along here, reliable witnesses report your front wheels leave the ground) and you are perched on top, ready for your photo opportunity!

The kids love driving around in mud, so next we played in the mud for awhile, before heading off onto another track. This one had even bigger muddy ruts, and you could easily get stuck on the high centre. I had the lead, driving somewhat contentedly along, more or less with right wheels on the centre, left wheels on the left shoulder, which was rapidly disappearing into a pile of brambles. I knew I had to get over onto the right shoulder, thought I picked the right space, but it was not to be.

All of a sudden, we were stopped with the right wheels in the right ditch, left wheels up on the high centre, frozen in time, and frozen at what looked to be about a thirty-degree angle. We did not breathe. The engine was running. I slowly turned the wheels full right, gave it some gas, and the tough little Syncro Kombi crawled up the right shoulder. We were safe again, and even level.

Derek watched this from behind. He reports that first he thought no one should move, because it seemed like we were so close to tipping. When we did not go over onto our side, he wanted to measure the angle to establish a data point: take a Syncro Camper with four pax to X degrees, and you will not (likely) tip. Much as I might like to have the data, we just wanted to get out! My wife and I both have some training and experience in judging bank angles of aircraft, and we are certain it was somewhere around 25-30 degrees.

Of course, all this stopped Derek who was following us, and, loosing momentum, he ended up stuck. We got some debris ( a refrigerator door, and wheel and tire), threw them into the offending mud hole, and he was out after a few tries and letting out a little more air from the tyres.

All in all, it was a beautiful fall day. Derek’s rule prevailed: ready and willing to get stuck, the Syncro Kombis went places and did things I never would have considered before. We all had a great time.

How Does VW's Syncro Viscous Coupling Work?

By Phill Lander

March 2000

The majority of motor vehicles on the road today have only one driven axle. This is perfectly sufficient for many driving situations. For special situations, however, such as winter driving in the mountains, off-road driving and in countries with inadequate road systems, all-wheel-drive is an advantage. This is why in recent years it has been increasingly applied to almost all types of vehicles.

The aim is a drive system which, ideally without the intervention of the driver, improves traction and also cornering dynamics whenever this is required by the frictional conditions.

In the VW Syncro 4WD system, this objective is achieved by an axial hydraulic coupling - referred to as ‘viscous coupling’ - in the drive train.

Construction - the viscous coupling consists of a drum-shaped housing, enclosed on all sides. Inside it are two independent, perforated and slotted steel-plate packs, of which one is splined to a shaft and driven by the engine and gearbox. The second plat pack is driven by a viscous (ie. thick and sticky) silicone oil, and they in turn drive an output shaft, likewise by means of a splined connection. The outer drum is rigidly connected to the pinion shaft of the rear-axle drive.

The viscous coupling is thus of similar construction to a multi-plate axial clutch. Unlike such clutches however, the viscous coupling does not have a disengaging device. The plates are free to move in the housing and on the shaft, and are slightly spaced apart. Power is transmitted mainly through the silicone oil by its resistance to shear.

Couplings of this type have the characteristic that, with very small differences in rotational speed, they allow a slight slip between input and output, but ‘stiffen’ as the difference in rotational speed increases - which, with further increasing shearing forces, results virtually in a friction-type drive. The friction heat generated in the silicone oil during shearing leads to the expansion of the fluid, which results in a rise in pressure in the housing.

To prevent excessive pressures in the hermetically sealed coupling housing, a small air bubble is included. This controls the extent of the pressure rise, which also influences the torque characteristics of the coupling. Through further effects occurring at the molecular level of the silicone oil, it is possible for the transmitted torque to increase to such an extent that one may speak almost of a rigid lockup. This is then where a self-regulating effect occurs. Since, in this condition, there is virtually no longer any relative motion between the plates, the temperature falls again, thereby reducing the pressure; both the temperature and pressure finally settle at a certain level according to the instantaneous tractive effort.

Fluid: High-viscosity silicone oil is used for viscous couplings because, in contrast to mineral oil, the viscosity of silicone oil falls to a lesser degree with rising temperature and, furthermore, the fluid remains stable even at very high temperature. Although it is known that siloxanes do not have any marked lubricating properties, particularly not between steel/steel, this very fact appears to guarantee the desired torque progression (hump). The siloxane fill is regarded as a life-long fill and the unit is permanently sealed.

Plates: The plate pack also has a decisive influence on the ability of the viscous coupling to transmit forces and torques. Both the thickness and number of plates, as well as their surface quality, have an effect on the shear behaviour. Their diameter is also a major factor (the torque is proportional to the 4th power of the effective radius).

The thickness of the plates tested varied between 0.25mm and 0.9mm. The plates are provided with slots and holes which, shaped by empirical means, promote the torque and shear behaviour and the shape stability.

Wear: The latest VW test results from the endurance test run bench revealed quite different wear patterns on the surface of the plates.

Whereas one mating surface pair of two neighbouring plates shows clear signs of smoothing, no wear at all is detectable on the surfaces of the next immediately adjacent pair. The appearance of the surfaces is as when installed, namely virtually as new. This phenomenon applies alternately to the entire set of plates. However, there were some exceptions: Two or more adjacent pairs were also found to have no signs of wear, just as two or more adjacent pairs were found with wear marks.

Seals: Since pressures of up to 100 bar may occur in extreme operation, high demands are placed on the shaft seals, especially as silicone oils have exceptionally high creepability; that is, they tend to creep through the narrowest of gaps even when under no pressure. This results in tightly fitted seals that consequently produce a basic friction of up to 30Nm.

Driving the Vehicle: Any difference between the rolling speed of the front and back axles resulted in almost simultaneous locking of the viscous coupling. The front axle always has precedence since it initiates lockup. Tests were done to determine the influence of different tyre diameters between front and rear, as this would allow a speed difference between the front and rear axles, and should activate the viscous coupling.

It was mainly the different tread depths that caused any differences between rolling circumferences (with equally sized wheels front and back); loading and air pressure were of little significance.

Measurements showed that in continuous operation with a slip speed of 5 rpm between front and rear, the viscous coupling does not yet enter the range of torque progression. This corresponds to the effect of a 3 mm difference in the tread depths on the 175/70SR14 tyres between front and rear wheels at a speed of 160 km/h. Anything larger and the visco coupling will begin to activate as it heats up.

Since, however, endurance tests have shown that the rates of wear on front and rear axles are virtually identical in the slip-controlled permanent four-wheel-drive, the danger of the viscous coupling overheating at high speed due to different rolling circumferences virtually eliminates itself.